Triple layer Dragonskin coating successfully takes on steel

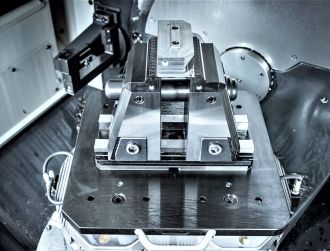

Many things work better as a team; this is nothing new. But wear-protection coatings working together to provide better performance is. This is exactly what Ceratizit has achieved with the new CTCM245 cutting material grade, combining three layers in the Dragonskin coating to give high-alloy steels something to fear.

Chromium-containing materials such as tool steels, martensitic stainless steels or high-alloy austenitic stainless steels are no easy task for machine operators. This is due to their high forming capacity, high ductility, tendency to stick to the tool as well as strain hardening and low heat conductivity. "If these properties break you out in a sweat, you can now relax: Our new CTCM245 cutting material grade is the right solution, even for such challenging materials," says Robert Frei, Milling Product Manager at Ceratizit.

Skillful layering

Skillful layering

The poor heat dissipation via the chip and inevitably higher tool temperature, in particular, called for a special approach to wear protection. The answer was a triple layer with a CVD process, in which each individual layer is already high performance in its own right, but really triumphs together as a team. "We chose a very tough substrate as a basis, that is extremely wear- and temperature resistant, and thanks to its incredible hardness, ensures a high resistance to breakage. A compound layer ensures that the combination of layers is effective, including by preventing negative effects due to diffusion," explains Robert Frei. To reduce abrasive and flank wear, a TiCN layer for high hardness and toughness is added. Finally, an Al2O3 layer ensures outstanding temperature resistance while reducing flank and crater wear.

Impressive performance, with or without lubricant

Thus the CTCM245 is virtually predestined for dry machining. Those who are now thinking that this means the machining parameters will hit rock bottom need not worry: "Despite the lack of cooling lubricant, the cutting speeds remain high. As thermal shocks are avoided, the CTCM245 indexable inserts reward the machine operator with reliable processes, outstanding tool life and strong performance. The CTCM245 really knows how to impress across the board, even when it comes to tricky applications," explains Robert Frei. CTCM245 will be available from stock in a wide range of indexable insert variants from round to four and eight cutting edges from September 2020.