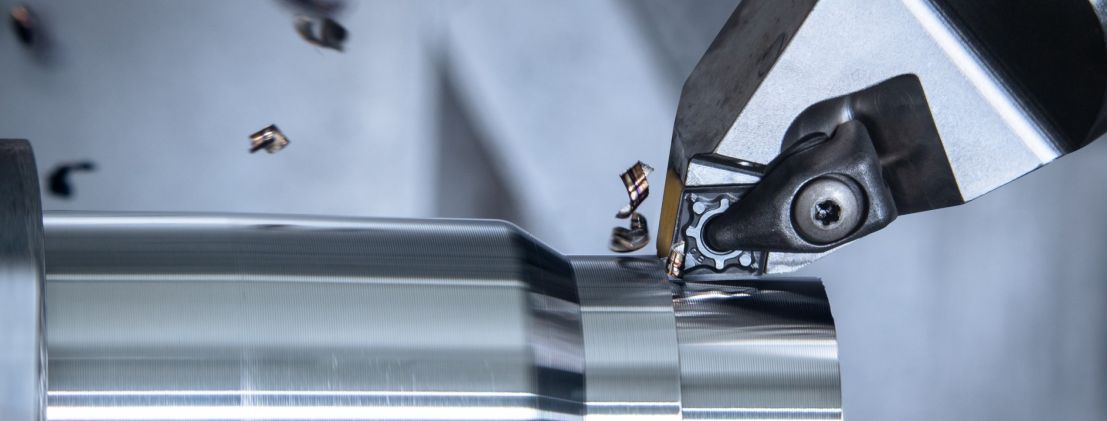

Ceratizit introduces new cutting insert that warns before breakage

Machining steel is anything but simple. Experienced machining specialists can all agree on this and are open to any solution that helps them turn ISO-P steel. That is why Ceratizit has put its turning grades to the test and ‘refined’ them where necessary.

ISO-P steels are by far the biggest material group in metal machining as it includes materials such as ductile, low-carbon steels right through to high-alloy steel grades. Added to this are variations in hardness, application types and machining conditions during turning operations. To make choosing an appropriate indexable insert grade easier, the turning specialists at Ceratizit have developed their own indexable insert grades and tailored them to the enormous variety of ISO-P materials.

For steely types and tough nuts

"The indexable inserts for our grades CTCP135-P, CTCP125-P and CTCP115-P have significantly boosted output in comparison with their predecessors: twenty-percent-longer service lives speak for themselves and make our turning tools even more appealing," says Stefan Karl, Product Manager Cutting Tools at Ceratizit. Anyone who fails to look closely enough at alternatives and best-practice when selecting an indexable insert grade is squandering major potential savings.

To enhance productivity for its customers Ceratizit has rethought its new turning grades, from the substrate to the geometries, right through to the Dragonskin coating – for optimal process security and hardness of cutting edges so that they can withstand the extreme temperatures in the cutting zone without plastic deformation. This ensures that they are prepared for every challenge, regardless of whether extremely hard or tough materials need to be machined.

Dragonskin produces hard facts

The innovative Dragonskin coating is crucial to the performance capability of the new steel turning grades. Its optimised structure is designed to increase tool life and reduce machining time. Mechanical post-treatment enables Ceratizit to achieve the layer surface's unique state of residual stress, which pays off in terms of increased process security, especially in large-scale production.

The CTCP115-P (ISO P15) grade is particularly suitable for smooth cuts with stable cutting conditions and continuous cuts. CERATIZIT has also provided grades CTCP125-P (ISO P25) for turning operations from finishing to rough machining and CTCP135-P (ISO P35) for cuts in unstable and difficult conditions.

Process-secure thanks to wear detection

When approaching the end of its life cycle, every cutting insert experiences a drop in performance. If this is detected too late, the machining quality may have already reduced significantly. "This is even worse if the tool is pushed right to its limit where it can fail in the middle of a process. In this case, the defective cutting insert is the least of your problems. The damaged workpiece presents a much more serious issue," says Stefan Karl knowingly. However, if the user identifies the extent of wear directly using the new indexable insert indicator layer, they can replace it in a timely manner. "A lot of our customers wanted this feature, which is why we have incorporated it into the latest generation of our steel turning grade in the form of the special Dragonskin coating – for stable and conflict-free processes!"