Weingärtner and CERATIZIT join forces to optimize turbine shaft production

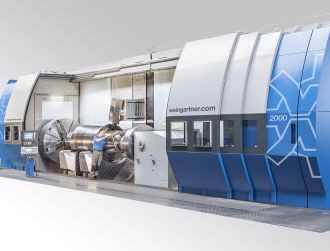

The task was demanding, the time frame challenging: Weingärtner Maschinenbau, based in Kirchham in Upper Austria, scaled up the concept of its mpmc 1200 machining center for an American power engineering group. The resulting mpmc 2000S is able to completely machine workpieces weighing up to 60 tonnes. A decisive contribution to this success story was made by the top-class brand Cutting Solutions by CERATIZIT. The carbide experts from Reutte, Austria, delivered the overall machining concept, including all the important tools. As well as achieving maximum machining quality, the machining time for the giant turbine shaft – which is used in gas or vapor turbine power plants – has been reduced by two-thirds compared to the time previously required for this process.

One high tensile steel blank worth 200,000 dollars

When the first meeting with the American customer was arranged with Weingärtner at EMO in September 2013, the company had already done two years of research to find a convincing concept for complete machining of these turbine shafts featuring an innovative component geometry. One of the big challenges was that the turning diameter of the component is up to two meters. "Until now, the workpiece weight between chuck and tailstock was limited to a maximum of 30 tonnes. We had already thought about how we could scale up our mpmc 1200 machining center to accommodate larger turning diameters and heavier work pieces. In this respect we were a step ahead of our competitors," says Werner Pommer from the engineering and sales department at Weingärtner Maschinenbau. This innovative approach paid off. Weingärtner received the order to deliver the machine for processing the turbine shaft destined for use in a gas turbine power plant. From the contract being awarded to the delivery of the machine, Weingärtner had only 20 months time. The situation was made all the more challenging by the fact that there was only one high tensile steel blank worth 200,000 dollars available to make the prototype.

Finding a strong partner

A decisive success factor for optimal utilization of the machine's potential are the tools applied for this purpose. Therefore, Weingärtner did not take the choice of its supplier lightly. First of all, six potential suppliers were invited to carry out simple milling tests. The results were evaluated using a matrix with the most important criteria for selection. In the second phase of the evaluation process, two of the preselected suppliers produced special tools which were tested in-house on the mpmc 1200, which has an identical machining concept. "Cutting Solutions by CERATIZIT convinced us in terms of productivity, process security and dimensional accuracy," says Pommer. "For the milling tests we used the SILVERSTAR from the new grade universe. We were very confident that we would obtain outstanding results using grade CTPP235 for this material group," continues Peter Uttenthaler, sales area manager for North and South America from Cutting Solutions by CERATIZIT.

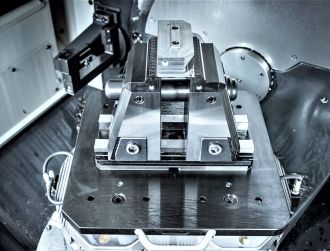

By December 2014, Weingärtner had found its partner for developing and delivering the tooling concept: Cutting Solutions by CERATIZIT. The most important tools are

- the high feed milling cutters with the new SILVERSTAR CTPP235 grade as a cutting material,

- the extremely precise solid carbide profile milling cutters with multiple cutting edges for the finish milling of the dovetail grooves,

- the MaxiDrill 900 insert drill for particularly deep holes with a diameter of up to 70 mm and

- the HX parting and grooving system for large parting and grooving widths with maximum stability.

Each of these tools contributes to the excellent economic efficiency of the overall process. Alfred Hofegger, head of OEM services at the top-class brand Cutting Solutions by CERATIZIT, who was in charge as project leader and technical counselor right from the start, points out that the milling concept ensures very high productivity and thus short machining times. Furthermore, the solid carbide profile milling cutters convinced thanks to their excellent tool life and perfect dimensional accuracy. The HX parting and grooving system also features very good chip control combined with relatively low cutting forces. "You can say that in this machining center we apply tools which satisfy maximum demands but altogether cost less than the tools used until now for similar tasks," says Pommer.

Available at any time

Thanks to its individual logistics concept, the top-class brand Cutting Solutions by CERATIZIT ensures 100 % availability of all tools at any time. This was part of the project and an important criterion for the customer with regard to the choice of the tool supplier. A rolling forecast guarantees that the customer's tool requirements can be calculated in advance. CERATIZIT benefits from the fact that the company has its own logistics center in Kempten, Germany, and also a U.S. subsidiary, both important elements in the logistics concept developed. "It was also considered a positive fact that we were able to organize the regrinding of the tools through our affiliate Promax Tools, a Californian manufacturer of solid carbide tools, directly in the U.S.," explains Peter Uttenthaler. According to Weingärtner another advantage and evidence of the extreme commitment of everybody involved was that the American CERATIZIT employee responsible for the project spent two weeks in Kirchham in order to become acquainted with the component, the tools which are used and the machining parameters.

Reduced machining costs by two-thirds

"What we have achieved here is the result of a great team performance," says Uttenthaler. He underlines that both parties could always rely on each other in every single phase of this demanding project. Werner Pommer: "The task was extremely demanding considering the tight time frame we had been given. We broke it down into individual work packages and planned and worked through each one step by step. Creativity backed up by engineering was vital." In his opinion, Alfred Hofegger was one of the key players in this project thanks to his excellent technical advice throughout the project. Both sides are proud of the fact that the result ultimately has even exceeded the expectations. The overall machining time including tool changes is only around 130 hours. Originally the goal was to reduce the machining costs by half. In fact, they were reduced by two-thirds. Dominik Weingärtner, vice-president of the family-owned company, is also delighted that Weingärtner and CERATIZIT, both of them Austrian companies with an extremely high share of exports, were able to demonstrate that together they are strong partners for demanding customers all around the world. He can well imagine taking on further projects with the partners from Reutte, Austria and admits: "Culturally speaking it makes things easier when two Austrians communicate with each other. We can really be proud of the technology from our region." It seems very likely that we will be hearing more from the team Weingärtner and Cutting Solutions by CERATIZIT.