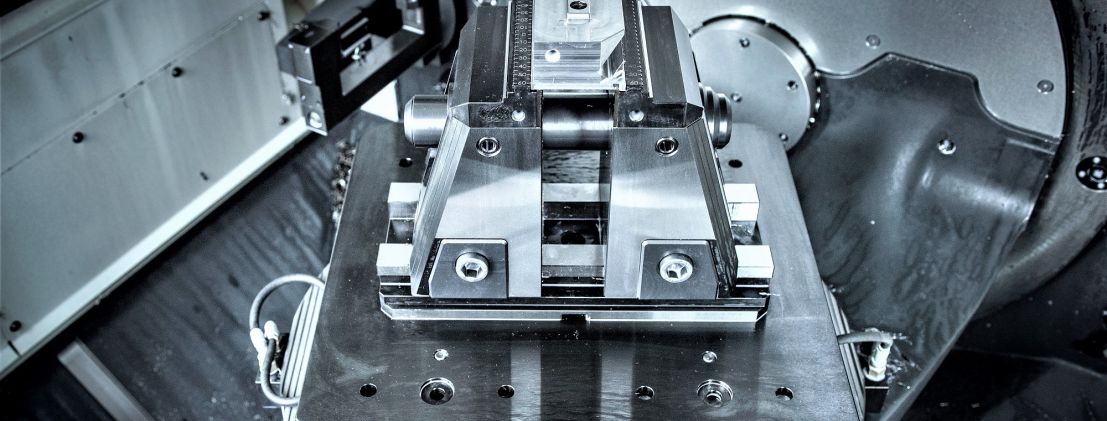

Ceratizit 5-axis vice for challenging machining

The WNT X5G-Z from CERATIZIT is a new, efficient and highly precise clamping system for machining centers. The most impressive feature of the WNT X5G-Z 5-axis clamping system is its optimized access from all sides, which allows components to be machined with five or even six axes. What is more, the 5-axis vice is very easy to operate and significantly reduces the setup time.

The sophisticated design of the WNT X5G-Z is immediately apparent: The lean, tapered contour of the two (mobile) fixed jaws provides the spindle head/tool with optimum access to the workpiece. The jaws contain elastomer elements that damp vibrations, thereby playing a role in improved surface quality and increasing the service life of the tool and spindle.

The system jaws and their adapter also have distinctive features. They sit on a special dovetail guide that the user manually clicks them into – in just a matter of seconds with no screws or tools required. The structural design incorporates a pull-down action. This means that after the clamping process, the tool is secured with great precision and tends to be pulled downwards in the clamping device through redirection of the forces, which considerably minimizes any lifting of the workpiece.

Quick-change jaws

Ceratizit offers 14 different system jaws with widths of 40, 65, 80 and 125 mm, of which two 125 jaws are already included in the scope of supply of a new X5G-Z as part of the basic equipment. The quick-change jaws have a classic L-shape and are designed as indexable jaws. The open-angle means they can be used inwards or outwards – a feature that opens up additional options, without costing extra.

The X5G-Z clamping system comes in five models and two heights, which differ in the length of their base bodies. The shortest measures 330 mm; while the other models are 430, 500, 630 and 800 mm long. The mechanical spindle which ensures the workpiece is clamped between the jaws has a basic clamping stroke of 140 mm as standard (without conversion). It can be easily extended for larger components up to a clamping range of 690 mm – provided the base body is sufficiently long. A quick-change system means conversion takes just a few minutes and can be carried out (like the system jaw exchange) without tools. Another plus point comes in the form of the fully encapsulated spindle, which protects it from chips and makes it almost maintenance-free.

A smart, and as yet unique solution has been developed for machining the sixth side. To do so, the user fixes the second fixed jaw, responsible for the clamping stroke, in place with a screw. Once this is done, the workpiece is pulled onto the jaws through an active pull-down action. This ensures that the jaws do not tip up and that the sixth side can be machined to a very high level of quality. Thus the X5G-Z can be used for complete 5-side machining on a 5-axis machine with a clamping device.