GFMS gives AgieCharmilles CUT P Pro wire EDMs five new features

The AgieCharmilles CUT P Pro series represents the latest generation of EDM machines. It offers customers high flexibility and speed, as well as maximum efficiency, combined with lower overall costs and less impact on the environment through reduced wire consumption. All this is possible thanks to five new features: ISPS, iWire, Turbo Tech, SMART wire and Uniqua, which are available on all AgieCharmilles CUT P Pro machines.

In addition, the unique Quadrax fix table construction allows to have a maximum table load, the X-Y and U-V directions have the same travel and include a patented axis collision system using a double measurement system.

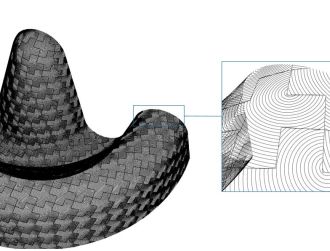

Improved and secure cutting process

The Spark Track platform provides monitoring of the spark distribution all along the wire. The ISPS module - an intelligent spark protection system - optimizes the cutting process without the risk of wire breakage. Using the data collected and processed by Spark Track, ISPS can automatically control and adjust the cutting parameters. This ensures an improved and safe cutting process that avoids wire breakage and provides optimal machine efficiency. The machine automatically adapts to different requirements without the need for fine-tuning, so that the result is perfect from the very first cut.

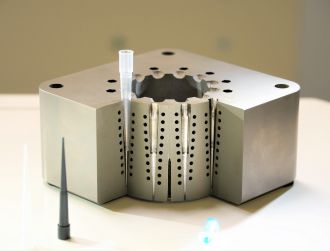

Reduced wire usage

The iWire add-on software module, based on the Spark Track platform, reduces the use of wire, especially for parts with large height differences or when the top or bottom ends cannot be placed against the part. The reduction depends on the working conditions and the application. The best performance is achieved with certified wires from GF Machining Solutions. SMART wire spools are equipped with RFID chips able to store the wire characteristic and traceability-related data. SMART wire automatically checks the wire loaded on the machine to ensure a correct use every time.

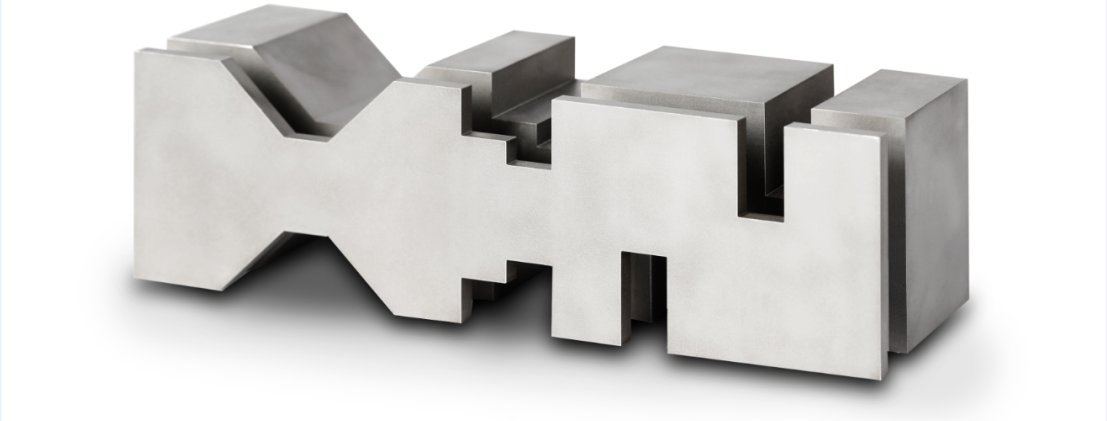

Speed and precision

Turbo Tech, a new standard technology that is faster than the Speed technology currently used on wire EDM machines, is compatible with the Spark Track platform. It represents an excellent compromise between speed and accuracy in both good and poor flushing conditions. Turbo Tech is available for all brass wires (for speed and quality) and integrates with the Uniqua control system or AC CUT HMI. With shorter total processing time and reduced wire consumption, the technology is as modern as it is durable.

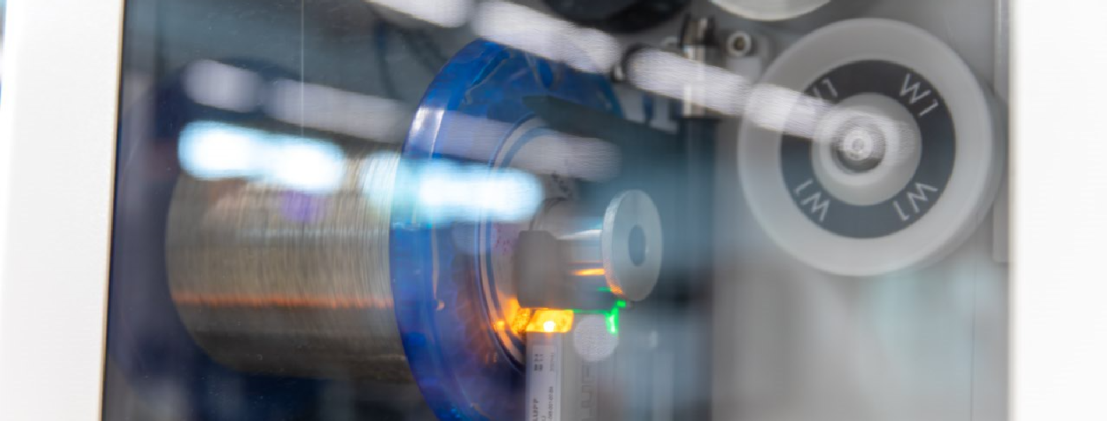

Uniqua user interface

The Uniqua user interface from GF Machining Solutions increases productivity and allows you to review priorities at any time to get the most out of your machines. With its intuitive workflow and fast learning curve, it simplifies the operator's work by adapting to the way he works. It also allows the operator to manage the shop floor and modify the program with ease. Integrated assistance and instructions are available at all times. Therefore, Uniqua is a user-friendly solution for regular users who are used to ISO programming as well as beginners.