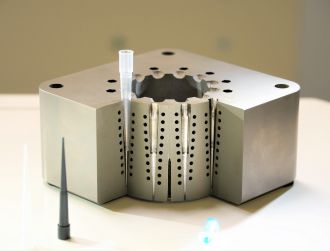

GF Machining Solutions provides platform rConnect for Milling, EDM and Laser

GF Machining Solutions rConnect is an in-depth remote machine tool analysis. It translates the Industry 4.0 vision of GF Machining Solutions of the smart factory of the future into a clear and usable solution for customers.

As manufacturing undergoes a digital transformation accelerated by expanding technologies including cyber-physical systems, the Internet of Things and the Internet of Services, opportunities are arising for businesses to increase their competitiveness by ensuring maximum machine uptime. That is the point of GF Machining Solutions Customer Services’ rConnect technology. As a central communication platform for its Milling, EDM and Laser technologies, rConnect is evidence of how the GF Division is advancing the Industry 4.0 vision of the smart factory of the future by helping businesses ensure maximum machine uptime and increase their competitiveness.

Real time remote assistance

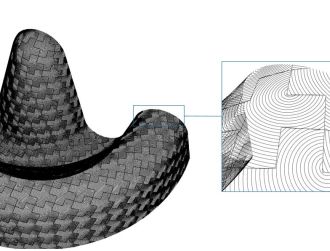

rConnect offers Live Remote Assistance (LRA), allowing customer-authorized remote assistance and therefore connects the customer with the local diagnostics center and the GF Machining Solutions plants in real time. LRA allows Customer Services to inspect a machine tool remotely with diagnostics performed by a GF Machining Solutions technician or the customer. Any resulting maintenance is performed on site by a service engineer.

Clear customer benefits with LRA

LRA’s customer cockpit is the user interface for the machine operator, maintainer or operations manager. It enables central access to GF Machining Solutions’ digital services and provides the operator with support in the daily maintenance of the machine. For example, it provides an overview of all maintenance due on the machine. The user can view current status messages and call up machine performance reports.

The customer benefits of LRA are clear: faster diagnoses and interventions when machine issues arise, significantly less machine downtime and, consequently, higher continuous productivity. With LRA, information can be shared between the customer and GF Machining Solutions via audio, video, chat, whiteboard, file transfer, screen sharing, and system access. All interactions are logged, and a record is created. Behind rConnect and LRA is instant virtual private network allowing highly secure access to the machine and certified with TÜViT Trusted Product Certificate.

Accel trough commitment and partnerships

The best value delivered by LRA and rConnect is direct result of GF Machining Solutions’ commitment to customers and its long Industry 4.0 partnerships with leading European research institutes including the University of Birmingham, the University of Geneva, the Swiss Federal Technical Institute in Zurich, RWTH Aachen University and the Fraunhofer Institute.