GF Machining Solutions released new CAM software for Laser machines

GF Machining Solutions released version 1.12.5 of its CAM software for texturing, engraving and micromachining Laser machines. This release includes two major new features: 3DCurvesTM and FlexiBlastTM, incorporated in LaserDesignTM.

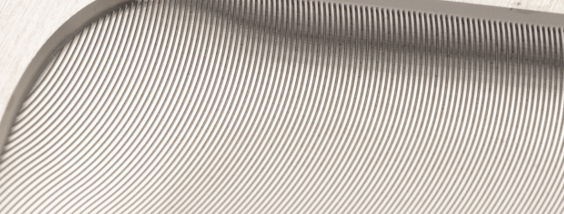

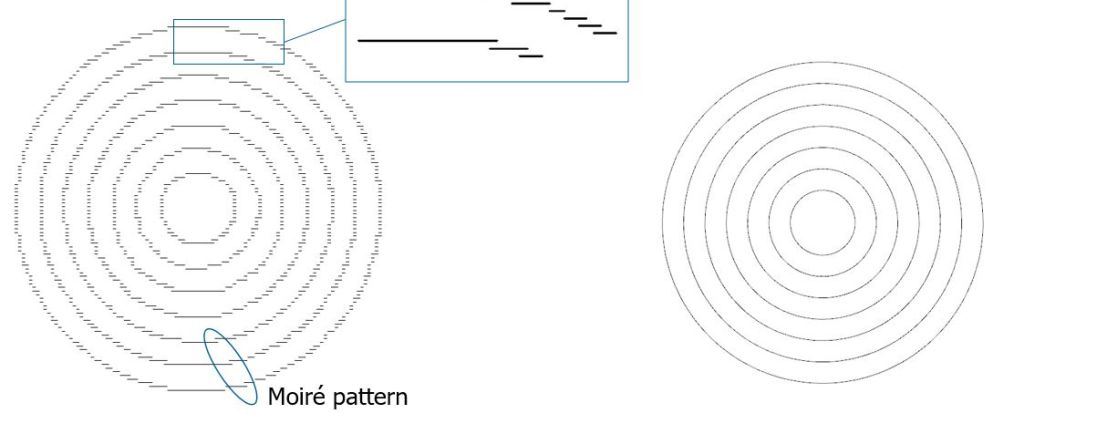

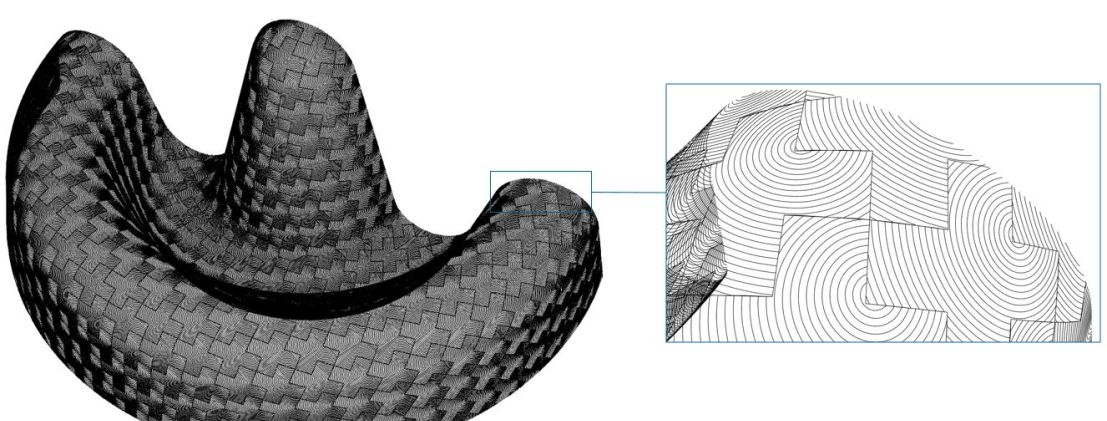

The first new functionality of this release called 3DCurvesTM allows users to significantly increase design capabilities while eliminating potential undesirable optical effects on laser engraved parts. 3DCurvesTM enables a novel approach when creating fine-line patterns and textures. Users no longer need to go through a classical hatching process based on a grayscale bitmap, but thanks to 3DcurvesTM can engrave directly with a single continuous laser path following each individual polyline.

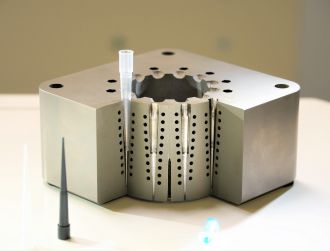

This new technology is of great interest for the production of textures with lines requiring high precision, for example for plastic parts used in the ICT or the automotive industries, or for directly engraved parts in the watchmaking or jewelry industries. 3DCurvesTM allows designers to create unprecedented designs applied in 2D with GF Machining Solutions' LASER P range of machines. It also offers the possibility to create curves virtually on complex 3D parts and molds with the LASER S range of machines. The technology uses polylines and not images, which are limited by their bitmap resolution, to orientate the Laser vectors in the local coordinate system.

Signature blasting capabilities

FlexiBlastTM builds on GF Machining Solutions' signature blasting capabilities by combining them with a grayscale image, allowing controlling its intensity. For each individual pixel, 216 shades of gray can be applied, each corresponding to a specific blasting intensity. This feature offers the possibility to render high-definition photo-realistic images on any material. Moreover, it gives users the ability to increase the depth perception with very shallow textures, which allows reducing production time drastically without any hardware modification. Fading textures and morphing can be achieved without altering the surface geometry. FlexiBlastTM can be used to apply a finishing layer to complement LaserDesignTM textures.

FlexiBlastTM offers advantages such as high definition with photo-realistic rendering, the creation of very fine textures with a significant rendering of depth and shallower textures for easier plastic demolding and faster machining times. The mold cleaning after the plastic injection becomes effortless since less plastic remains on the mold after the injection process. Therefore, there is a significant gain in productivity.