GF Machining Solutions prevents damage to the spindle with Machine Spindle Protect module

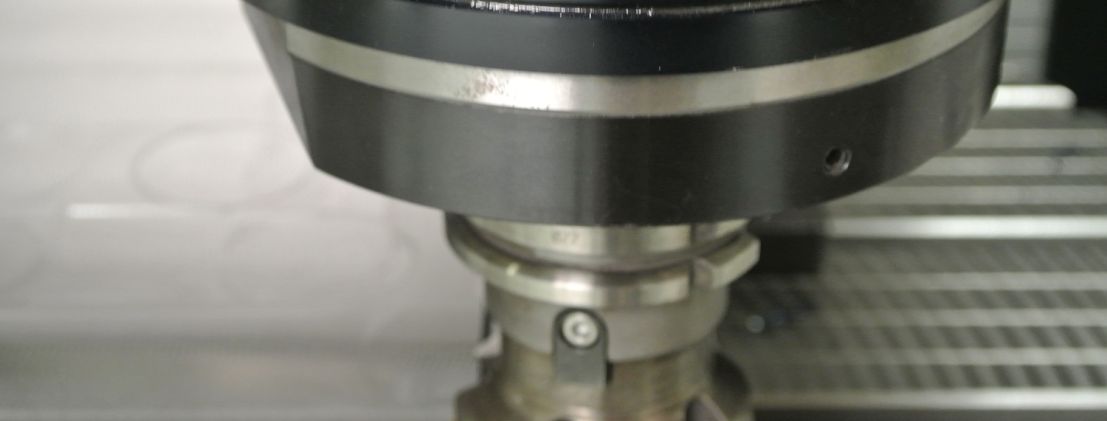

GF Machining Solution’s innovative Machine Spindle Protect (MSP) module prevents damage to the Spindle, protects the machine, reduces downtime and reduces costs in the event of unexpected Spindle collision.

With the MSP smart machine module, GF Machining Solutions has developed a revolutionary Spindle collision protection that offers customers a range of solid advantages: The system prevents damage to the Spindle, protects the machine geometry, reduces machine downtime and therefore contributes to cost reductions in the case of unexpected and undesired Spindle collisions.

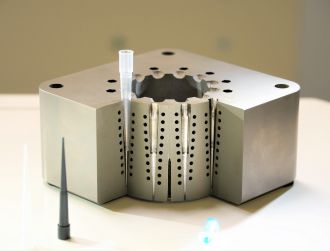

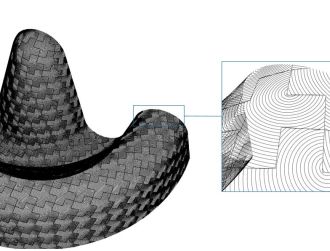

To properly assess the value of MSP, it's worth taking a look at its functionality: Collisions usually occur when a new CNC program is first executed. The MSP module protects the machine and Spindle during the installation process. This module makes it possible for the Spindle to absorb axial and lateral collisions. MSP restores perfect accuracy as soon as the Spindle has returned to normal operating conditions after the collision.

During the setup process, the machine works reliably in a secured mode with reduced travel speed that permits general processing operations. The combination of MSP and a reduced travel speed ensures that both Spindle and machine are protected against collision damages. If the manufacturing conditions require higher travel speeds, the machine can be operated in standard mode with full axis speed.

The continuously active MSP module protects the machine geometry, reduces machine downtimes, guarantees full cost control, reduces insurance costs for machine damages and makes it easier to calculate the availability of the machine. It is available from GF Machining Solutions’ Spindle manufacturer Step-Tec, together with the 20,000 rpm motor spindle.