GF Machining Solutions introduced new FORM family of die-sinking EDM machines

Whatever the current—or future—die-sinking electrical discharge machining (DSEDM) challenge, GF Machining Solutions’ AgieCharmilles new FORM family of die-sinking electrical discharge machining (DSEDM) machines are future-shaping solutions to advance manufacturers’ success.

The AgieCharmilles FORM X, FORM S, FORM P and FORM E series advance their forebears’ software and technical innovation, such as the renowned AC FORM human-machine interface (HMI) and GF Machining Solutions’ legendary EDM know-how. Whether the requirement is a single machine for straightforward use or full Automation, these new, easily integrable FORM solutions position users to meet every challenge, with greater flexibility and machining accuracy to eliminate costly manual operations.

These eco-friendly solutions offer Econowatt technology to save energy, a variety of Industry 4.0-oriented connectivity features to support manufacturers’ digital transformation, and eTracking software for EDM process monitoring and full traceability.

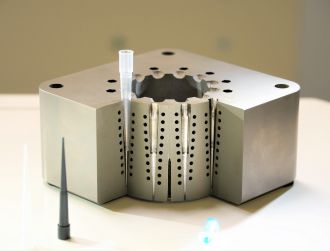

From faster rib machining to micromachining, the AgieCharmilles FORM family of DSEDM solutions is evidence of GF Machining Solutions’ continued and significant investments to advance DSEDM research. The result is that AgieCharmilles FORM series users achieve performance like never before in machining with graphite and copper. Perfectly repeatable machining of microcavities is just one example of the manufacturing challenges expertly resolved by this range of DSEDM solutions. In parallel, this series’ iGAP technology enables the rigidity of plastic injection molded end products with deep, plastic-reinforced ribs; it ensures fast, accurate machining of rib cavities with superior respect for the required demolding taper and VDI homogeneity throughout the cavity surface.

Manufacturers requiring maximum use of their AgieCharmilles FORM machine can exploit the range’s eConnectivity features and MTConnect capability to stay informed of the machine’s status. Automation is another way AgieCharmilles FORM series machine users can extend their productivity: In today’s fast-paced manufacturing environment, unattended manufacturing is a must, so the AgieCharmilles FORM E, P, S and X series solutions can be connected to external robots and offer integrated pallet as well as electrode changing solutions.

AgieCharmilles FORM X: uncompromising accuracy

Extreme accuracy, highest precision in mass production, and unparalleled productivity come together as future-shaping solutions with the AgieCharmilles FORM X series. This series’ TECFORM ensures highest accuracy and reproducibility on both big and small parts. This is due to the fixed table and stiff machine base delivering perfect positioning accuracy along the entire axis travel. The result: high precision throughout the machining area.

Furthermore, manufacturers’ mass production of highly precise micro parts is assured by the AgieCharmilles FORM X series’ precision-enhancing qualities. High-quality, automated mass production is easily within reach, thanks to these machines’ dynamic thermostabilization.

As manufacturers face ever-shorter delivery times, the AgieCharmilles FORM X series delivers high running time—no manual intervention necessary—thanks to its vast Automation capabilities. These include the accommodation of linear, rotary or robot pallet and electrode changers, as well as smart features such as Part Express and Job List management. Users can ramp up their profitability by automating their production, thanks to the

AgieCharmilles FORM X series’ ability to accommodate two front-oriented machines on each side of the robot.

AgieCharmilles FORM S: big success in micro-profiles

GF Machining Solutions’ AgieCharmilles FORM S solutions open new fields for miniaturization, optimize productivity, ensure lasting accuracy, and have the Automation readiness to position users for the future.

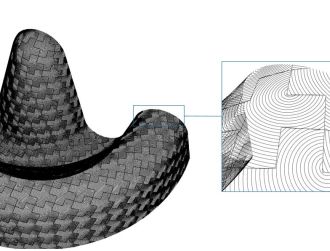

New fields of miniaturization are opened by the maximum respect for details provided by these solutions’ Intelligent Speed Power Generator (ISPG) evolution and specific microtechnologies. The latest-generation ISPG makes it possible to use a smaller-than-ever spark gap to remove minute amounts of material in order to achieve finest geometric details.

At the same time, AgieCharmilles FORM S 350 users achieve more with less by using fewer electrodes to achieve greater detail. Behind this achievement lies this solution’s process, enabling such a small electrical current that electrode wear becomes insignificant. Consequently, only a few electrodes are needed to machine cavities and this represents a significant advantage over similar products.

High, lasting accuracy is made possible by a specific controlled process during production of the AgieCharmilles FORM S series, so the machine retains stable accuracy across its lifetime. Stable performance is ensured by this solution’s standard thermostabilization equipment.

Moreover, the AgieCharmilles FORM S 350 is Automation-ready and GF Machining Solutions has a perfect Automation configuration to meet every need, whether the requirement is a simple linear tool changer or any kind of robot in any cell.

AgieCharmilles FORM P: boost running-time with efficiency

As the preferred choice for automated parts production with adapted investment cost, the AgieCharmilles FORM P series puts perfect results and high productivity at the user’s fingertips.

Perfect results are enabled by the intuitive, easy-to-learn and easy-to-use die-sinking EDM process ensured by GF Machining Solutions’ AC FORM HMI. Designed for productivity, the FORM P series leads the way in high running time without manual intervention, thanks to the series’ multiple Automation choices from a linear, rotary or robot pallet or electrode changer as well as smart features like Part Express and Job List management.

Manufacturers’ speed and productivity are advanced by GF Machining Solutions’ die-sinking EDM embedded in the FORM P series’ EDM process management. The ISPG, in association with the TECFORM EXPERT system, maximizes surface finish and homogeneity by generating the ideal EDM spark settings.

AgieCharmilles FORM E: best value for users’ investment

This multifaceted performer delivers best value for the investment in the production of molds and parts. It offers superb accessibility, automated dielectric management, extended Automation capabilities, ever-evolving technological improvements, and the availability of GF Machining Solutions Customer Services’ rConnect world of digital services.

Automatic dielectric management increases machining time while reducing human intervention. Filling and emptying the work tank is now automatic, and the dielectric height can be adjusted while running a program. Furthermore, the AgieCharmilles FORM E series offers extended Automation capabilities, including linear tool changers and external robot connections (WPT1+) from System 3R.

Thanks to GF Machining Solutions’ continuous improvement of EDM technology, AgieCharmilles FORM E users get the EDM performance necessary to address their daily challenges. With rConnect, GF Machining Solutions continues to push technological boundaries to deliver the future of services—today. As the machine tool industry’s most in-depth digital service platform, rConnect represents this GF Division’s Industry 4.0 vision

of intelligent and high-performing services. AgieCharmilles FORM X, S, P and E series machines are all rConnect ready.