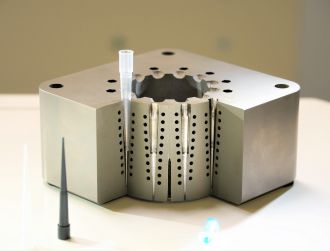

GF Machining Solutions has developed a wire EDM machine, especially for the energy and aerospace sector. The new CUT S 400 Dedicated is designed to meet the high demands regarding accuracy and efficiency in producing turbine components.

According to GF Machining Solutions, the CUT S 400 Dedicated is the result of ten years of development and close cooperation with customers and partners from the energy and aerospace industries. The wire EDM machine is tailor-made for the production of a wide range of turbine component shapes and sizes. Unlike other wire EDM machines from GF Machining Solutions, where accuracy is paramount, the CUT S 400 Dedicated focuses primarily on increasing productivity through ease of maintenance and reliability improvements, so that the machine can serve as an efficient production machine.

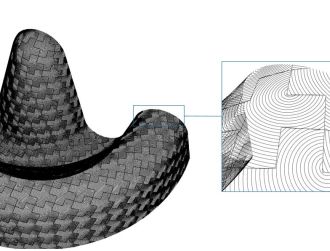

The CUT S 400 Dedicated integrates technologies such as pivoting and rotating axes for precise and flexible machining of both light and heavy workpieces with a mass of up to 300 kg. The machine has a reach of 400 mm x 315 mm x 256 mm (XxYxZ) and is suitable for workpieces with a maximum diameter of 680 mm. The integration of the Intelligent Speed Power Generator (ISPG), 3D printed heads for more effective flushing and Spark Track technology make the machine even more productive. Spark Track optimizes spark energy in real time to prevent wire breaks and maximize cutting speed.

Improved traceability

In the energy and aerospace sector, traceability is essential. That is why GF Machining Solutions has developed the eTracking software. This enables comprehensive monitoring of machine status, order progress and processing traceability in real-time. In addition, the software allows a quick response to any deviations, guaranteeing consistent quality and performance.

The CUT S 400 Dedicated is completely designed for unmanned production. It has a wire capacity of up to 45 kg, six efficient filters and optimal integration with automation solutions. The SMART wire spools with RFID technology improve traceability and efficiency in the production process. All these automation options, combined with a 28% reduction in daily energy consumption, make the CUT S 400 Dedicated a future-proof machine.