GF Machining Solutions focuses on applications at the GF Global Solutions Days

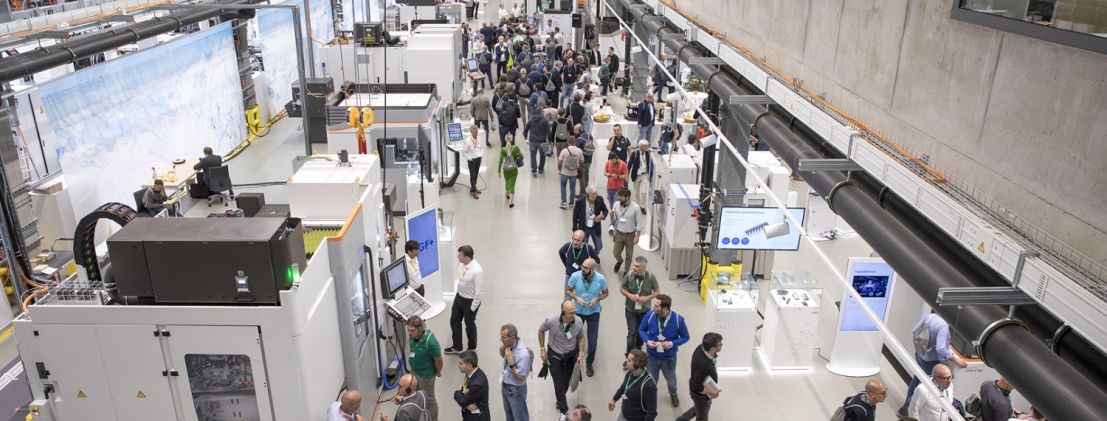

At its second important customer event in Switzerland this year, GF Machining Solutions invited VIP customers to its headquarters in Biel from 23 to 25 May 2023 to give them an overview of machines and applications in a real-life environment and give them a look inside the main milling plant and headquarters in Biel (Switzerland).

Applications and technology were the focus of this event. Visitors were able to learn more about fuel cell applications made with Milling and plastic mold manufacturing with Laser and explore the possibilities of Grinding and Milling on the same machine. Customers attending the event were given a tour of the factory and had the possibility to experience live demonstrations on many different stations in Biel's Center of Competence (CoC). The stations were dedicated to Milling, EDM and Laser and highlighted the new solutions Mikron MILL P 800 U S and MILL S 600 U, AgieCharmilles CUT X 350 and AgieCharmilles LASER S 1200 fs. During the factory tour, customers were able to take a look at the Milling assembly and the Step-Tec spindles production line, while at the stations they were able to learn more about the specific capabilities of the presented machines on challenging applications.

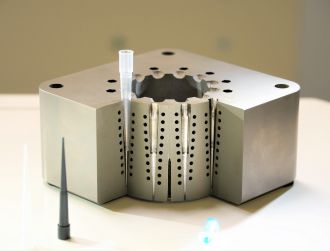

Five-axis milling

In Milling, GF Machining Solutions demonstrated customers the advantages and functionalities of the high-performance five-axis milling machine MILL P 800 U S, a high dynamic solution with an acceleration of 1.7g and a very convenient footprint when combined with automation, and the MILL S 600 U, which allows for Milling and Grinding on the same machine. With these Milling solutions, customers are ready to reduce their manufacturing times and increase their productivity, even for small batches. On the MILL P 800 U S and the MILL S 600 U, applications displayed were a multi-cavity plastic injection mold, which requires high-efficient machining, and a syringe accessories mold, which includes up to four automated production processes depending on the required component design features (Die-sinking, Milling, Laser and Automation).

EDM technology

The CUT X 350 brings together over 100 years of experience in wire-cutting EDM by providing a new level of accuracy. This solution is capable of holding extreme pitch positioning and contouring capabilities for superb part quality, making it suited for stamping, molding and micro-machining applications in the Electronic Components (EC), Medical and Automotive markets. Applications displayed at the Global Solutions Days in combination with this machine were watch components that require a surface finish of Ra 0.30 µ and a profile accuracy of 1.5 µm, and an application for the ICT market segment with an accuracy of 1.5 µm and a surface finish of Ra 0.15 µm.

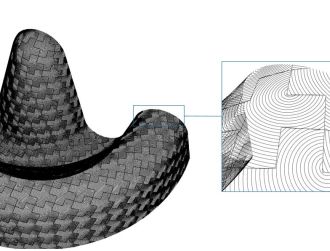

Laser machining

The main innovation from GF Machining Solutions in the Laser technology in 2023 is the LASER S 1200 U fs, which is equipped with a fiber femtosecond Laser. This novelty on this highly efficient machine ensures a Laser machining process capable of creating finest details with enhanced quality while maintaining a high performance on large-size parts. Examples of applications machined on the LASER S shown at the event were a lotus flower with a different texture on every petal and a headlamp mold core for the Automotive segment, which represents different manufacturing challenges like the handling of a vast amount of micro-features and the management of small tools.