GF Machining Solutions CUT P wire EDM is faster, more flexible and offers higher quality

Engineered to simplify even the most demanding applications, GF Machining Solutions’ all-new AgieCharmilles CUT P series of solutions brings the Limitless Possibilities of new intelligence to the wire-cutting electrical discharge machining (WEDM) process.

The fourth industrial revolution—also known as Industry 4.0—represents the new era of innovation shaping the way manufacturers work. The new AgieCharmilles CUT P wire EDM series delivers new intelligence to advance their speed, flexibility and quality while helping them get to the heart of even the most critical applications in electronic components, automotive and medtech.

Designed for productivity

From producing a surgical tool weighing only a few grams to machining a six-ton die-casting mold for automotive, every detail of the AgieCharmilles CUT P series is designed to help manufacturers expand their business opportunities. The new state-of-the-art Intelligent Power Generator (IPG) enables precision parts and helps mold-and-die manufacturers to increase their cutting performance by 20 percent. Completely adapted for System 3R’s Tooling and Automation solutions, the AgieCharmilles CUT P series helps users optimize their machine uptime. In addition, running costs are minimized by an array of innovative capabilities such as Automatic Slug Welding (ASW), Automatic Slug Management (ASM), ECO machining, and an improved Econowatt function. This translates into reduced time to market and faster production at lower costs.

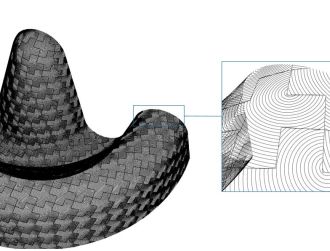

Ideal for every application

Whether the job at hand requires micromachining or macromachining, the AgieCharmilles CUT P series helps manufacturers master complexity and expand their business to reach perfect performance in any situation. The mechanical design together with the thermostabilization and machining repeatability boost accuracy down to 2 µm and yield surface finishes down to Ra 0.08 µm. Advanced taper accuracy below 10 seconds with straightness, sharp contours and no lines is now easily available with the AgieCharmilles CUT P series’ EXPERT systems. At the same time, the unique collision protection system prevents costly machine maintenance and ensures long-term accuracy and reliability. On top of that, the retractable 3D probing system delivers a faster setup and complete Automation setup to drive the success of complex parts manufacturers. All of these benefits—including the more than 600 available technologies made possible by the new, cutting-edge IPG—allow manufacturers to cut their costs by up to 20 percent.

Always available

The fourth industrial revolution is changing the way manufacturers work. Productivity and machine availability are essential for profitability. This is why the AgieCharmilles CUT P series focuses on putting SMART and connected solutions at manufacturers’ fingertips.

SMART consumables include, for example, radio-frequency identification (RFID) chips integrated into wires to eliminate the risk of errors. They facilitate the quick replacement of consumables, avert breakdowns, minimize stock, and ensure complete process traceability. At the same time, System 3R’s WorkShopManager and CellManager software take process administration and surveying to the next level. eTracking digitizes process monitoring as well as traceability and GF Machining Solutions’ rConnect suite of modular digital services keeps manufacturers connected to their machines anytime—wherever they are. Moreover, AgieCharmilles CUT P solutions increase tooling life, reduce scrapped parts, advance quality control, decrease the need for manual intervention, and allow manufacturers to work 100 percent automatically. The result: Manufacturers spend more time machining—and enjoy Limitless Possibilities in tackling complex applications and expanding their business horizons.

Advancing quality at GKN Sinter Metal AG

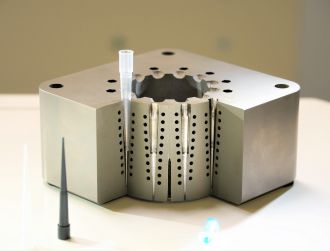

Quality is king in the fast-paced, zero-defects focused world of automotive manufacturing, where components are becoming ever more complex. That complexity drives the need for increasingly precise tools—the very specialty of GKN Sinter Metals AG’s tool shop.

GF Machining Solutions’ new AgieCharmilles CUT P 550 WEDM solution helps GKN Sinter Metals’ tool shop meet the automotive market’s demands for highest quality punches and dies. Proof of the value added by the AgieCharmilles CUT P series is in the highly precise punches and dies produced by the shop, says Tool Shop Manager Helmuth Ausserhofer.

“Our first priority is precision because it is directly connected to quality. Tall parts, like lower punches up to 400 mm in height and made of ASP 2023 steel, are a good example of the machining challenges we face. The AgieCharmilles CUT P 550 represents a step forward in terms of quality, especially on tall parts,” Ausserhofer says. “Our punches have to fit into the die with very small clearance of 3–8 microns. Our CUT P 550 delivers the highly reliable precision we need in order to achieve the quality our customers expect, 100 percent of the time.”

Another key contributor to precision—and thus quality—at GKN Sinter Metals is GF Machining Solutions’ certified 0.25, 0.15 and 0.1 mm diameter EDM wire.

“We tested various wires and the reliable quality of GF Machining Solutions wire is one of the best. GF Machining Solutions’ 0.25 mm wire is our standard, and the 0.15 and 0.1 mm wires help us precisely machine the smallest radii,” Ausserhofer explains. “Quality is king in tool making for automotive, so we use GF Machining Solutions wires.”

Together, the AgieCharmilles CUT P series’ precision-boosting capabilities, process reliability and certified wires help GKN Sinter Metals AG continue its long legacy of producing the highest quality tools for automotive manufacturing.