From 10 to 14 September 2024 CERATIZIT will be presenting numerous newly developed tool solutions at AMB in Stuttgart. Visitors can look forward to innovations such as the sustainable, high-performance ProAct-Mill milling cutter, exciting live machining demonstrations and digital services for the smart production line.

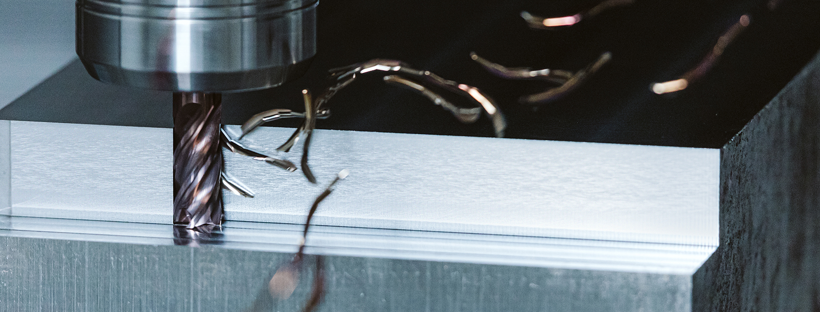

Steels, stainless steels or cast materials: Anyone who has to machine them all needs milling cutters that can be used universally for the best possible efficiency. CERATIZIT has added the solid carbide milling cutter ProACT-Mill to its portfolio as a new, independent product line made from the sustainable carbide upGRADE to ensure sustainability does not fall by the wayside. The ProACT-Mill combines the unrestricted performance of an all-round high-performance milling cutter with the most sustainable carbide substrate currently available from CERATIZIT. CERATIZIT thus provides its customers with an economic and ecological advantage thanks to the certified CO2 footprint in the form of a low product carbon footprint (PCF).

The optimised geometries and the newly developed coating of the ProACT-Mill are aimed at maximum performance in as many materials as possible as well as long tool life. The test results of the new series show that this is by no means a compromise: Compared to other universal tools, the milling cutters achieve up to 30% higher performance.

Live experience

AMB visitors can experience in numerous live demos that the ProAct-Mill delivers what it promises. ‘We want to show our customers and interested parties the performance that our sustainable ProAct-Mill milling cutter brings to the milling machine. To do this, we will be clamping it on the GROB machine we are bringing to AMB along with some of our other highlights. Together with the MaxiMill - 211-DC, the KUB Pentron and the AluLine CCR, it will produce something very special from aluminium,’ reveals Ramiro Bengochea, Director of Global Sales at CERATIZIT Deutschland GmbH. To mark the 30th anniversary of CERATIZIT's popular EcoCut line, oversized indexable inserts made of aluminium will be manufactured on-site.

Produce digitally, automate extensively

Digital services have been firmly anchored in the CERATIZIT portfolio for many years, such as the CERAsmart ToolScope monitoring and control system. This permanently records the signals generated from the cutting machine during the production process, visualises this data and thus provides important information for process control, machine protection and documentation. ‘In order to utilise the data generated during the process in a meaningful way for the machinist, it is analysed and processed in ToolScope and made available to the user. They can view the relevant data in our CERAsmart Cockpit and use it to optimise their processes,’ emphasises Andreas Kordwig, Director of Global Product Management Cutting Tools.

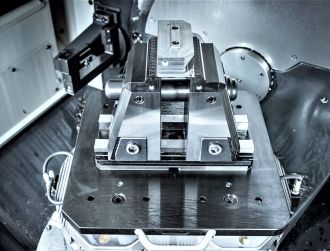

CERATIZIT demonstrates what sophisticated automation solutions can look like with the R-C2 workpiece automation as a solution between pallet automation and direct robot loading. This means less set-up work and a significant increase in flexibility. The CERATIZIT experts will also be revealing the other advantages of the system and how it can be used effectively at the trade fair stand.

Machining can also create motorised works of art: A motorbike with an extravagant cyberpunk look and exhilarating performance, manufactured by the SBAY Motor Company from San Roque in Spain, will be on display at AMB. ‘Many of the components are specially designed and manufactured - using our high-performance tools. At our stand, we will be happy to show how SBAY transforms the wildest dreams of custom bike fans into customised motorbikes with that extra performance,’ says Ramiro Bengochea.

The CERATIZIT Group can be found in Hall 3, Stand B10.

Planning to Visit AMB? Get 50% Off with Our Discount Code!

Use code 24SPAENER50 to enjoy a 50% discount on all AMB tickets. Purchase your discounted tickets here.