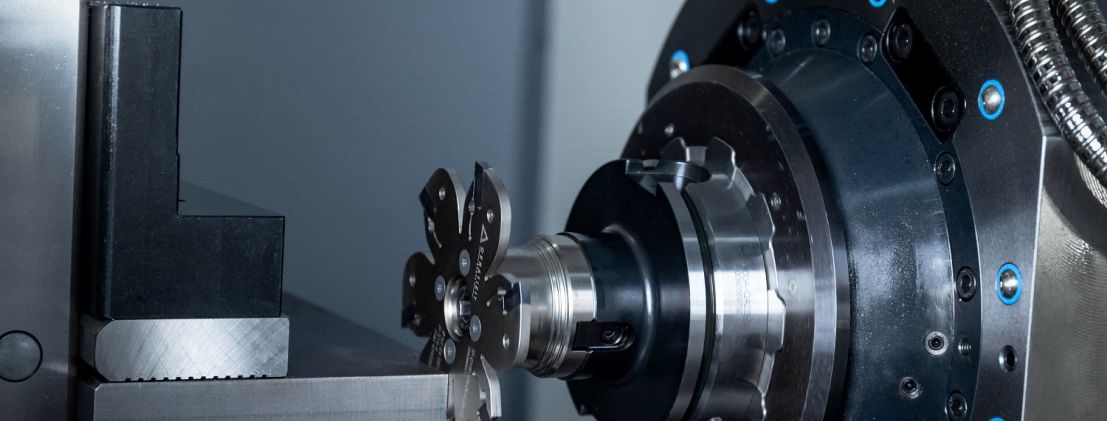

Ceratizit MaxiMill – Slot-SX for reliable grooving, slotting and parting off

Grooving, slotting, parting off – errors while performing any of these operations may result in the entire machining process wasted and an unusable workpiece. Powerful side and face milling cutters from Ceratizit's new MaxiMill – Slot-SX series with through coolant can now provide the highest levels of process security and optimum performance – even with diameters as large as 250 mm.

The milling tools with indexable inserts from the Ceratizit MaxiMill series have a secure place in the machining market thanks to their high-quality standards and broad applications. "What we've been lacking is a program for slot milling that would enable our customers to machine slots and grooves and carry out parting operations in a process-secure manner. This led to the development of our MaxiMill – Slot-SX, which is modeled on the existing grooving inserts from the SX system and extends our portfolio with a range of robust solutions," explained Robert Frei, Product Manager at Ceratizit.

Large selection of cutting inserts

The choice of materials that machine operators come across every day is generally very broad, which means that the range of tools used has to be just as large. Robert Frei commented: "As the MaxiMill – Slot-SX allows us to use cutting inserts from our proven grooving system, this means we can cover practically the entire range of options under ISO P/M/K/N/S, leaving nothing out – even for high-performance applications!"

Ceratizit customers can choose between standard DIN connections, threads or shell mill adapters from the varied tool holder range. The tools can thus be used with all machining centres, milling and turning machines.

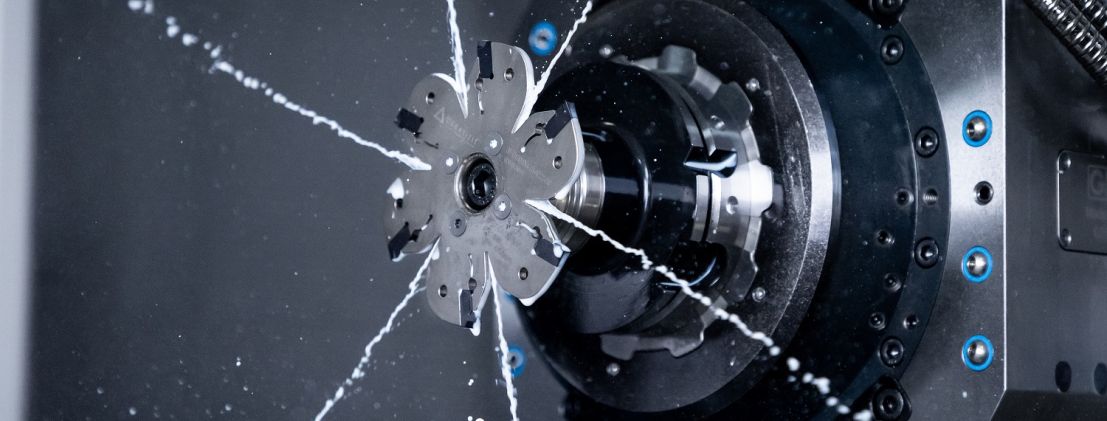

Coolant supply up to 250 mm diameter

Chip management is first and foremost during slot milling, especially in the case of narrow and deep slots. "It will naturally work even without a cooling lubricant, but the option with internal coolant holes (IKK) has significant advantages," claimed Robert Frei. "That's because anything that's time-consuming or even damaging for the machining process – such as removing chips from the slots by hand, not to mention chip jams and material adhesion with serious consequences for the workpiece – simply do not occur if you have an effective supply of cooling lubricant. And because drawbacks like these are often exacerbated with deep slots, we offer internal coolant holes up to 250 mm in diameter!" This improves surface quality and heat control at the same time, ensuring a process-secure machining operation. A welcome side-effect is that working with a cooling lubricant significantly increases tool service life.

Inserts changed safely

In addition to the performance of a system, simple handling is another factor that makes the machine operator's day much easier. The MaxiMill – Slot-SX therefore uses the patented SX clamping key when changing inserts. Thanks to its lever, this key speeds up changing operations and always maintains the correct clamping force. "Nothing is ever unnecessarily squeezed, overstressed or in the worst case deformed: our user-friendly solution reduces insert seat wear and keeps the indexable insert in a precise and stable position – giving excellent slot quality and machining stability," added Robert Frei.