CERATIZIT AluLine - Micro Featuring High-Precision Micro Milling Cutters for Complex Miniature Parts

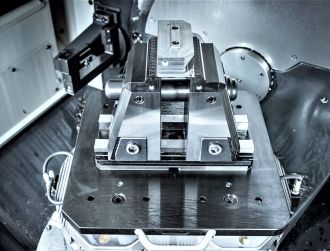

Everywhere you look workpieces are getting smaller. Whether it's in medical applications, next- gen smartphones or handcrafted precision time pieces, the mantra is the same: the smaller, the better. It's therefore no surprise that the trend towards miniaturization also extends to the tools involved. It's here where CERATIZIT comes into play with its revamped AluLine – Micro. These micro milling cutters have been adapted to meet current industry demands and feature a shrinkable 4-millimetre shank, cutting diameters from 0.2 to 3.0 mm, projection lengths from 3xD to 15xD, as well as an extremely thin DLC coating.

And should you think that tools designed for large diameters can simply be scaled down to be used on smaller sizes, well you are sorely mistaken. Manufacturing milling cutters with diameters down to 0.2 mm requires enormous know-how and-crucially—an adapted substrate ensuring the requisite tool stability. It's in precisely these mini use cases where CERATZIT makes an enormous impact thanks to its robust portfolio of micro tools for use in a wide variety of materials and cutting environments.

μm-range tolerances

As part sizes diminish, tolerances play an increasingly key role. With the completely new AluLine - Micro, high-precision professionals can rely on the pinpoint accuracy of milling cutters with 3 μm at 0.2 mm diameter. The 4 mm tool shank, which is now also compatible for shrink- fit holders, also contributes to precision results by ensuring optimum concentricity and the highest contour quality for components. CERATIZIT uses an ultra-fine grain substrate for the new AluLine - Micro milling cutters, which is particularly recommended for use in abrasive aluminium alloys. "From the substrate and geometry to the extremely thin and ultra-smooth DLC coating, our new AluLine - Micro milling cutters are perfect for machining aluminium, copper and other non-ferrous metals in the micro range—an absolute must for high-precision and economical processes," says Michael Wucher, Product Manager at CERATIZIT.

Sharp cutting edges with ultra-thin DLC coating

For many professionals, machining aluminum is associated with sticky chips and built-up edge formations already an issue in macro machining and considerably even worse with micro milling. For precisely this reason, AluLine - Micro milling cutters have been outfitted with a special polishing grind that enables more homogeneous cutting edges and significantly improves chip flow. In addition, the micro milling cutters now feature an ultra-smooth DLC (diamond like carbon) coating. Together with the special geometry of the tools, sticky aluminum chips are now easily removed from the cutting zone.

DLC coatings are extremely advantageous as they can be applied as particularly thin coats so that they do not impair the delicate geometries and sharp cutting edges. Another added plus for DLCs is that they give AluLine - Micro milling cutters a considerable increase in performance and tool life-two essential factors for stable and economical processes.

Large portfolio of micro tools for machining aluminium

CERATIZIT offers different tool variations for the AluLine - Micro. Ranging from radius and torus milling cutters to end mills with corner chamfer, they come in various shank versions, different lengths, geometries and diameter ranges from 0.2 mm to 3.0 mm or from 3xD to 15xD projection length. With this product range, machinists can focus on the task at hand and carry out a large part of the micro-machining of aluminum alloys, copper and other non-ferrous metals. "Moreover, our selection of tools is also ideally positioned for other applications in the micro range," says Michael Wucher. "In addition to our micro milling cutters, we also have the newly developed and innovative micro drills from the WTX - Micro-Pilot series, which are ideal for drilling the most impossible of workpiece topographies without the need for a mirror finish- which saves both time and money."