Subsea oil wells strive for larger components in highly wear-resistant materials

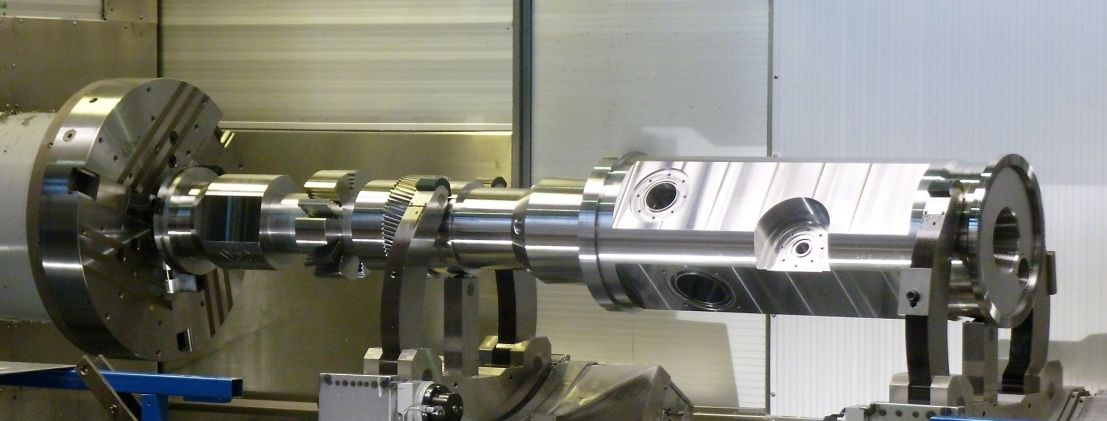

Subsea oil wells strive for larger drill tube diameters increasing output capacity. Thus components such as valve blocks are required to be much larger than ever. Subsequently, such parts exceed the limits of common production facilities.

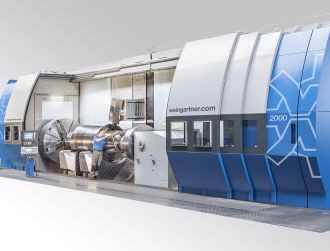

The size and complexity of modern valve blocks, particularly the cutting of highly wear-resistant materials like INCONEL 625 and INCONEL 718, imply high demands for the machine tools in terms of rigidity and cutting performance. The Weingärtner Multi Production Machining Centers mpmc 1200, mpmc 1500 and mpmc 2000 open new dimensions for large-scale manufacturing. 220 hp turning power at 30,000 ft lb of torque, in combination with 100 hp milling power at 1400 ft lb of torque offer unmatched cutting performance.

Versatility within a single machine tool slashes production cost

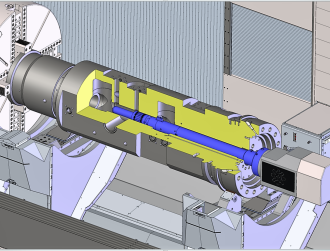

The Weingärtner modular machining head system allows for the automatic exchange of the HD milling head to a High-Speed milling head with 14,000 RPM, or seat pocket boring heads for the large subsea valve blocks.

Fulfilling the quality demands of long and heavy tools a maximum system rigidity is required. Weingärtner mpmc class machine tools offer ideal conditions for efficient manufacturing.