Smart Factory: fully automated flexible production with automatic clamping device changeover from Hainbuch

For years, production costs have been heading in only one direction, that is to say, steeply upward, while the demand is for ever-lower manufacturing prices. On top of this, there is a lack of skilled workers. These are the challenges that confront many manufacturers, including WTO, a maker of static and driven precision toolholders. The solution appears to be obvious: a fully automated production hall.

In series production, one can always rely on established methods, but for small batch sizes, new automation technologies first have to be developed and integrated into an overall system. Why? Because clamping devices, for example, must be changed over several times a day, which presents enormous challenges in terms of process and safety. Working together with Hainbuch, the Marbach-based clamping equipment manufacturer, WTO has overcome the obstacles by performing a closely coordinated series of measurements and tests. In WTO's new Smart Factory, all processes are automated, with robots inserting the components, changing the clamping devices, and driverless transport systems bringing everything from A to B. Since the end of 2022, production of one of the components of the driven tools has been running autonomously 24/7 in batch sizes from 1 to 100. This is a milestone for WTO and Hainbuch after a 3-year development phase.

Smart Factory was the only option

WTO is based in Ohlsbach near Offenburg, but outside the major cities there is a lack of skilled workers. Due to demographic developments, this situation will continue to worsen. In addition, fewer and fewer people want to become machine operators and there is less and less willingness to work in shifts. Sascha Tschiggfrei, managing director of WTO, recognised this early on and in 2016 began to think about solutions. "Skilled workers are one thing, cost increases are another. Because we operate internationally, the competitive pressure is great. Some make the choice to relocate abroad to produce at lower cost. However, we wanted to keep our location in Germany, so we had to react to ensure our company stays competitive over the long term. Our future lies with the Smart Factory, producing around the clock and operating fully automatically. It gives us a competitive edge and also allows us to attract more highly qualified people", said Tschiggfrei.

The search for an exclusive partner

For this mammoth project, WTO wanted an exclusive partner for the clamping equipment, with the commitment and expertise to contribute with suitable new designs. "We worked out the technical details in project teams. The questions were: How do we clamp the workpieces, how can we automate the clamping, and how can we change the clamping equipment automatically? The goal was for the machines to execute changeovers completely autonomously. This requires clamping devices that have this capability. In addition, we have a high precision grinding process, with a maximum 3 µm tolerance range", said Tschiggfrei. Once the Smart Factory concept was in place, the next step was to look for a partner. Since WTO and Hainbuch had already worked successfully together on various international projects, Hainbuch was the partner of choice. At the end of 2019, they began the initial discussions to define the clamping device requirements. The design proposals developed by Hainbuch were accepted.

The start button is pressed

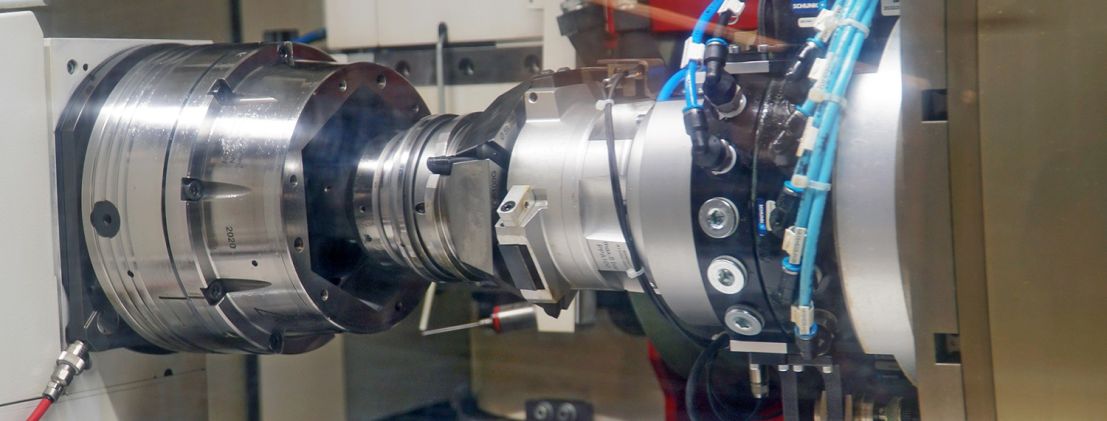

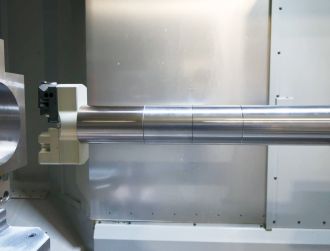

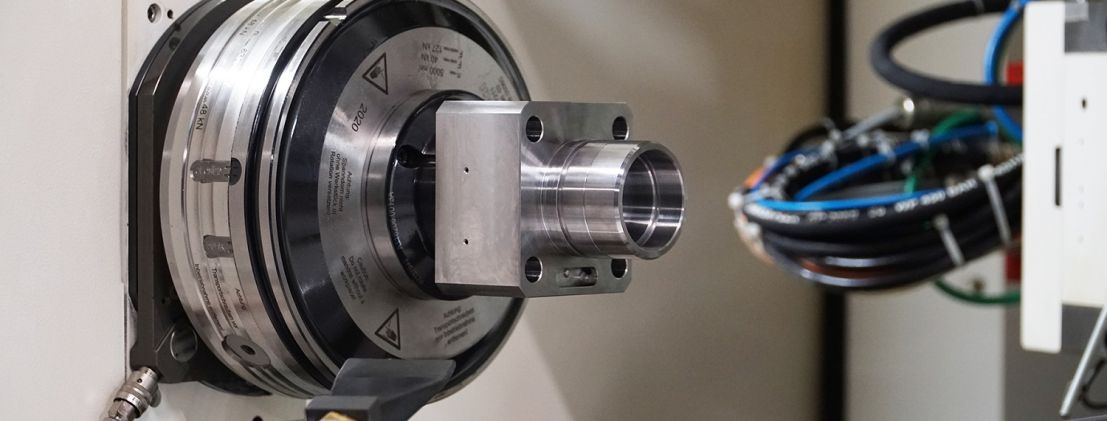

WTO has an existing production hall with over 50 CNC machines. Clamping on these machines is mainly done with jaw chucks, and retooling and alignment for each OP is done manually. The first completely unmanned manufacturing process to be implemented in the Smart Factory was to produce a housing, with soft machining followed by hard machining. Tschiggfrei explained further: "The machines in the Smart Factory are all new. They are standard machines, but they are specifically adapted to allow the automatic changeover of clamping devices using a robot.” Hainbuch was to equip four machines with clamping devices. Two turning/milling centres in one cell with internal clamping on the counter spindle, and two cylindrical grinding machines in another cell, one with external clamping and one with internal clamping. To clamp externally for grinding, Hainbuch already had a standard chuck, the Toplus AC 100 with axial pull-back. For the various housings, there are now 18 clamping sets, consisting of a clamping head with end-stop, which are automatically changed over in the chuck. However, for the internal clamping when turning and grinding, a completely new development was required. It was based on the existing Maxxos T211 clamping mandrel, however in this version with safety checks, a specific mandrel was developed.

Stringent requirements on the clamping device

For Björn Schiesling, a design engineer in Hainbuch's automation department who has been involved from the beginning, there are fundamental requirements that must be considered in automation. "What is missing from automatic workholding changeover? It is the employee who cleans the contact surfaces. Even the smallest dirt particles cause the accuracy to go out of specification. Then, there are the safety checks. Is the spindle allowed to rotate? Is it correctly tensioned? Is it sitting correctly? Can anything come loose? In general, all the things that are normally checked and adjusted by the operator. This is no longer the case with automation. For us, it was a huge challenge to implement these checks in the clamping devices. Of course, we also had to work out with the machine manufacturer how this could be implemented in terms of control technology by monitoring the stroke position. For example: to check by air sensing, I can provide the channels in the clamping device so that air sensing can be implemented. But the machine manufacturer has to implement the air supply and the sensors behind it that communicate with the machine control system. There were many stumbling blocks on the way to the final solution, but we were able to successfully overcome them," says Schiesling.

Safety has priority

For internal clamping, Hainbuch had also considered changing over the segment clamping bushes and end stops. But due to contamination at the front of the workpiece and the safety checks, only pre-equipped mandrels which are changed over automatically came under consideration. Schiesling explains: "There were too many pitfalls in keeping it clean. We simply don't have as much space with the mandrel as we do with the chuck. On top of that, we use the pull pin to pull the clamping bush onto a truncated pyramid. If we hadn't done that, we would have had to use the robot to insert an IT7 grade fit. But since the robots are somewhat imprecise, we would not have been able to make the changeover reliably”. Now, the grinding cell and the turning/milling cell each have ten pre-equipped Maxxos mandrels with a centrotex AC interface. These are kept in stock for the different housings with the appropriate set-up and are changed over automatically.

Hainbuch has more than met the requirements

Philipp Wußler, Grinding Division Manager at WTO, initially had major doubts as to whether everything would work. "Fortunately, these have vanished into thin air. The clamping devices meet all the requirements, be it cleanliness, accuracy and what is very important, repeatability. With every clamping mandrel changeover, we are within the required 3 µm," remarks Wußler with satisfaction. The automated manufacturing process has reduced the setup time by 25 percent compared to the old method, when jaw chucks had to be clamped, retooled by hand and jaws ground for accuracy. "Scrap has also been significantly reduced or is almost zero. This is because clamping used to be less accurate. Now we clamp with axial pull-back on the end stop and it's much more accurate. Once I have run-in the component, I know the next setup process will work fine. This means I no longer have any clamping device worries", adds Wußler. For WTO it is quite clear: If the clamping is safer, then the process is safer, too.

"The Smart Factory is designed so that the only manual operation is the delivery of the raw material. A driverless transport system even picks up the finished housings, which are inspected and measured in the production cell, and takes them from the machine into storage. The Smart Factory includes a command centre with offices where the manufacturing processes and programming are planned. The clamping devices and the definition of the handling parameters for the automation planned there as well," says Tschiggfrei. Further projects are already in the pipeline and Hainbuch will again be supplying the clamping devices and be involved in the start-up process. Tschiggfrei says in conclusion: "We are very satisfied. We wanted a partner to carry out this development project together with us. Hainbuch put everything into reaching the very last "µm". Mr. Schiesling and Mr. Wußler were passionately committed to the project. It takes people like that to successfully implement something like this. From my point of view, the outcome has been even better than expected.”