The NeoMill-Alu-QBig indexable insert milling cutter, developed by MAPAL, sets a new standard in high-volume aluminium milling. Designed specifically for high-performance machines prevalent in the aerospace industry, this cutting-edge tool offers an economical solution for achieving superior material removal rates.

Exceptional Material Removal Rates

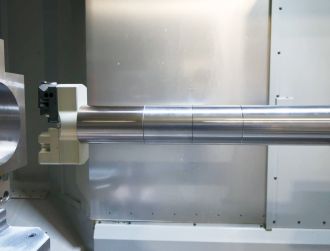

MAPAL's NeoMill-Alu-QBig takes full advantage of the fastest machines on the market, achieving a remarkable material removal rate of over 18 litres per minute. Moreover, it is also suitable for use on less powerful machines, taking into account the variety of spindle outputs (ranging from 40 to 80 kW) typically found in aircraft manufacturing. This flexibility makes it an ideal choice for manufacturers looking to optimize their production processes.

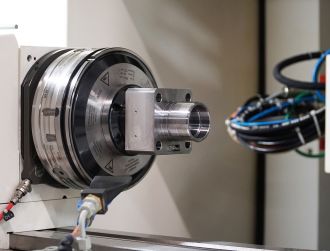

Innovative Design for Maximum Performance

To maximize material removal, the NeoMill-Alu-QBig is engineered for spindle speeds of up to 35,000 rpm, particularly with a diameter of 50 mm. The indexable inserts are securely held in place by screws with increased tensile strength, ensuring a tight fit despite high centrifugal forces. Weight-saving countersinks on the inserts add to the tool's efficiency. Furthermore, the tool body is equipped with a fine balancing system featuring four threaded bores for precise adjustment. This not only protects the machine spindle at high speeds but also achieves the highest possible surface finishes.

Precision and Efficiency in Cutting

Developed with a focus on low cutting forces and high precision, the NeoMill-Alu-QBig ensures high chip volumes and superior surface finishes of Ra 0.8 µm and Rz 4.0 µm for both rough and fine machining tasks. For machining wrought aluminium alloys, uncoated cutting edges with a highly positive rake angle and polished chip guiding stage are used, minimizing frictional resistance and reducing heat generation. The portfolio also includes PVD-coated indexable inserts for machining AlSi alloys and CVD-diamond-coated indexable inserts for diverse applications in the automotive and general machining industries.

Optimized Heat Dissipation and Chip Removal

MAPAL has integrated internal cooling and large chip spaces into the NeoMill-Alu-QBig to ensure optimal heat dissipation and efficient chip removal. The tool bodies are produced in a diameter range of 32 to 80 mm, compatible with both hollow shank taper and shank taper mounting tool variants.

By combining innovative design features and high-speed capabilities, the NeoMill-Alu-QBig from MAPAL offers an unparalleled solution for high-volume aluminium milling, enhancing productivity and efficiency for manufacturers in the aerospace and other demanding industries.