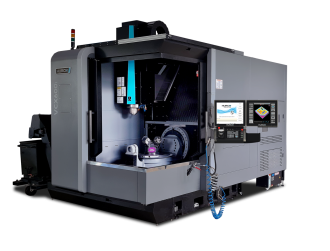

Starrag gives production machines online health check

Anyone who cares about the health of their production machines – i.e. their availability and productivity – should have checked them regularly. Since the middle of 2021, Starrag has offered an online version of its highly efficient Fingerprint service specifically for this purpose. This digital tool perfectly complements Starrag‘s range of services, being fast, cost-effective and, most importantly, revealing. The customer only has to take the machine out of production for one hour.

How does the online version of Fingerprint work? On the agreed date, Starrag Remote Service contacts the customer, who has already prepared the machine for the examination. Specifically, there should be an empty pallet on the machine and no tools should be loaded, to ensure that any risk of collision is excluded during the test runs. The machine operator enables access to Fingerprint on the machine. Only once this is done can the service technician remotely access the machine from Chemnitz. The service technician starts a specially developed program that executes various tasks, including frequency response analyses, vibration analyses and a circularity test. Furthermore, the power consumption of all machining axes is recorded, as well as the amount of contamination and wear on the linear measuring systems, alongside meter readings and temperature data. This data is analysed and compared with data that has been collected before. By the next working day at the latest, the customer receives a result report that breaks down all the conditions and, if applicable, includes suggestions on how to eliminate errors or carry out maintenance work.

State of wear

The advantages are considerable: Without any need for extensive disassembly and assembly work, the customer receives a quick and meaningful analysis of the state of wear of the main components of the machine. The bottom line is that it assists with increasing machine availability and productivity, extending machine lifetime and lowering workpiece costs. The online Fingerprint offer has been available since mid-2021 for all Heckert machines built in 2017 or later with Siemens Operate control. It is gradually being rolled out to other Starrag product ranges.

With the new online Fingerprint, Starrag offers a fast, qualified machine analysis. This can help save on maintenance and resource costs and prevents unplanned machine failures due to wear.