BIG KAISER is supporting the shift to clean energy production, by facilitating the precise and efficient machining of essential components. The power industry requires the fabrication of numerous complex parts, such as turbine cases, bearing-carrier casings, compressor cases, burners, blade-carrier rings, turbine shafts and pumps. These components demand high precision and cutting efficiency, with high feed rates and consistent cutting, even with widely used, harsh materials such as Waspaloy and Inconel.

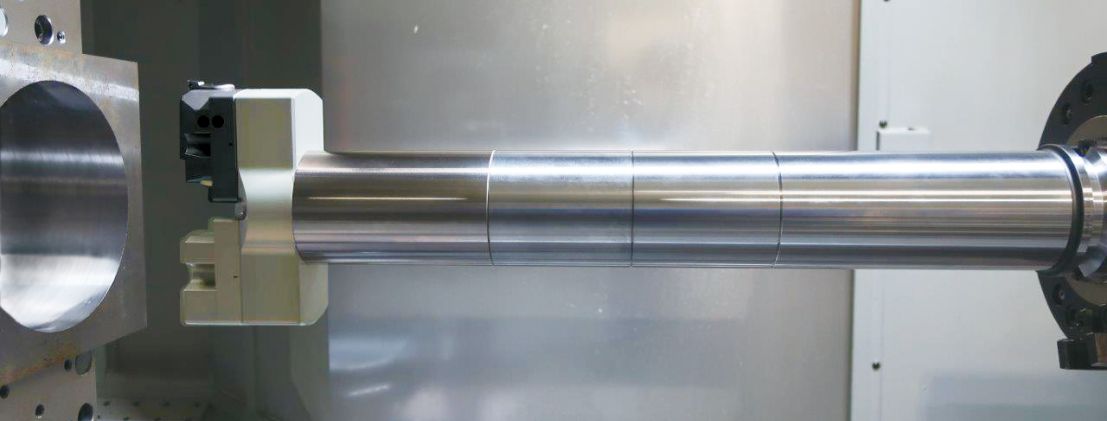

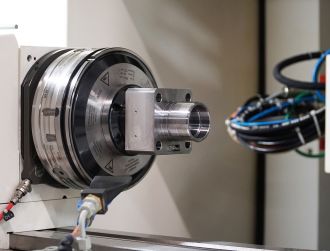

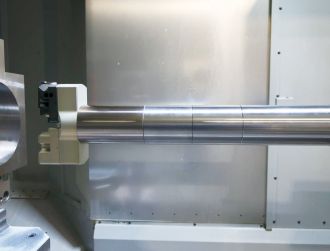

BIG KAISER’s range of tooling solutions includes multiple products that enable this kind of precise, efficient manufacturing. To give one specific example, BIG KAISER’s Smart Damper for large diameters is specifically designed for manufacturing bores in large workpieces, which makes it particularly useful in energy industries such as wind and hydropower.

Effective vibration control

The patented Smart Damper, available for diameters up to 320mm, incorporates advanced technology to provide precise and effective vibration control during boring operations on large diameters. “Due to its modularity and advanced damping capabilities, the Smart Damper enables significant increases in cutting speeds, thus allowing companies to increase productivity and reduce machining time,” explains Giampaolo Roccatello, Chief Sales & Marketing Officer for Europe at BIG KAISER.

“It also reduces unwanted vibrations that can compromise machining quality and accuracy,” continues Roccatello. “This helps improve the surface quality of machined parts, and therefore to reduce finishing costs and ensure compliance with stringent industry quality standards.”

Large-diameter boring industry

The Smart Damper is ideal for a wide range of applications in the large-diameter boring industry. It can be used for machining critical components for hydroelectric power plants, such as electric motor housings and turbine housings, as well as for the production of structural parts in the aviation industry, such as spars and structural parts. Its versatility and performance make it an indispensable tool for improving the efficiency and quality of machining in these demanding industries.