CERATIZIT's MonoThread Performance Cutters Boost Thread Milling Efficiency by 20%

Often the thread quality determines whether or not the final product is a success. As threads are typically produced at the very end of the entire machining process, the bar in terms of precision and process security is set very high. CERATIZIT’s Performance Line shank milling cutters, such as MonoThread – SGF and MonoThread – SFSE, deliver reliable quality in both regards. With a performance increase of up to 20% compared to the predecessor model, the latest generation boasts improved service life and an excellent price-performance ratio.

In recent years, thread milling has become a noteworthy alternative to tapping and thread forming or thread whirling, thanks in large part to the advantages of thread milling cutters. Instead of having a thread on the cutting edge, they have a corrected profile with spacing corresponding to the pitch. This leads to precision thread position and enables the production of dimensions with the same pitch in a variety of materials.

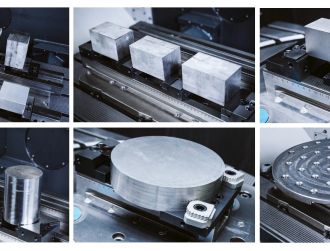

With the shank thread milling cutter MonoThread – SGF and MonoThread – SFSE, a shank thread milling cutter with chamfer facet, CERATIZIT has now launched two completely reworked tools from the Performance Line. In doing so, CERATIZIT’s tool developers have significantly optimized both, resulting in a performance increase of up to 20%.

Reliable processes thanks to thread milling

"Thread milling is ideal for all standardised thread profiles of all tolerances, and especially for asymmetrical, large and very expensive workpieces. This is because very short chips are produced, which ensures a much more reliable process," says Markus Mack, Product Manager at CERATIZIT. What's more, lower drive power is required of the machines used than for thread cutting. This also holds true when used in comparably difficult-to-machine materials, such as high-strength or tempered steels.

In addition, the process reduces tool costs, as a single tool can produce left and right threads with different thread tolerances plus blind and through holes. Unlike thread cutting, precision-milled threads can be produced along the entire length right down to the bottom of the hole.

Smooth thread even at high speed

If you compare the thread profiles of a tap with those of a thread milling cutter from the Performance Line, it is easy to see that the surface structure of the milled thread is much smoother, particularly on the thread flanks. The milled thread profile has hardly any edge breakage, while the tap pulls individual particles out of the material, leading to cratering. "Using coolant really helps remedy such situations. In the case of MonoThread – SGF and MonoThread – SFSE, they prevent material breakage due to their axial coolant supply," explains Markus Mack.

Thanks to its low cutting pressure, thread milling is also suitable for thin-walled components. And even at speed, MonoThread tools do not do things halfway: workpieces can be machined at high feed rates (vf) and a high cutting speed (vc), with short processing times to boot.

Sustainable thanks to regrinding

If a MonoThread milling cutter from the Performance Line is no longer able to achieve its full performance level after a lengthy period of use, there is no need to replace the tool just yet. Instead, they can be reground—sometimes even several times. This increases cost-effectiveness and conserves vital resources.