CERATIZIT Enhances Modular MaxiChange Exchangeable Head System with Grooving Operations

The MaxiChange exchangeable head system from CERATIZIT and its countless base holders and vibration-damped boring bars have become a flexible solution for a wide range of turning operations. CERATIZIT is now expanding its product range with the MaxiChange GX modular grooving system. Thanks to the internal coolant supply, the tools keep a cool head even in challenging conditions.

When complex components need to be produced in small to medium batches, this typically requires numerous different machining processes on the workpiece. To ensure that there is still enough space in the machine turret in spite of this, stable exchangeable head systems like the MaxiChange from CERATIZIT are being used more and more often as proven space and time savers. They reduce storage costs due to their compatibility with all base holders, meaning only the head needs to be exchanged to perform different tasks. At the same time, they shorten setup times, thereby increasing productivity without sacrificing process security.

The MaxiChange exchangeable head system is known for its quick and easy tool change feature. CERATIZIT Product Manager Paul Hoeckberg says, "We have engineered the design for maximum changeover precision and exceptional stability. At the same time, the modular design means it is extremely flexible and can be used for a variety of applications thanks to its wide selection of exchangeable heads. On top of these advantages, the MaxiChange GX also includes a grooving function for internal and external machining as well as axial and radial machining."

One system—unlimited possibilities

MaxiChange GX16 is available for the 25 mm interface size in groove widths of 2, 3 and 4 mm, and for 32 mm interfaces in widths of 4, 5 and 6 mm. The GX16 exchangeable heads can be used for both internal and external machining. The MaxiChange GX24 is available for the 40 mm interface size in groove widths of 3 and 4 mm and is ideal for axial machining.

-

The CERATIZIT MaxiChange GX modular exchangeable head system can be used for internal and external machining as well as axial and radial machining. -

CERATIZIT has added a grooving option to the MaxiChange GX modular exchangeable head system -

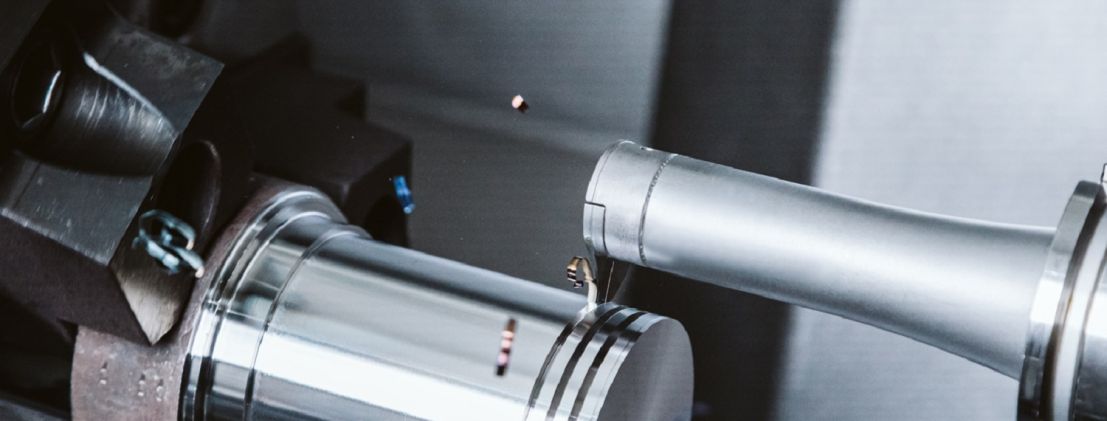

Thanks to the MaxiChange GX's internal coolant supply, chips in the groove are reliably flushed out with a high flow volume and wear to the tool is reduced.

Internal coolant supply

The biggest risks during grooving continue to be chip jams and extreme temperatures in the machining zone. To counteract this, CERATIZIT has equipped the new MaxiChange GX with an internal coolant supply, which reliably flushes out any chips in the groove with a high flow volume, thus reducing wear to the tool.

Anytime grooving operations with long overhangs and a tendency for vibrations need to be conducted, MaxiChange GX can be used in combination with the vibration-damped boring bar. "This enables our customers to boost performance and process security, which has the added bonus of delivering excellent surface qualities using vibration-damped adapters," says Paul Hoeckberg, revealing his tip for using the MaxiChange GX.