CERATIZIT launches ISO-P update for popular EcoCut series

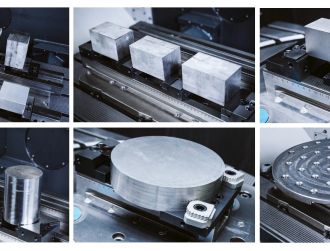

Machining steel is where many tools regularly find themselves at risk of biting off more than they can chew - in the truest sense of the word. But that doesn't have to be the case. With the updated version of the tried and tested EcoCut series, CERATIZIT is now delivering high-performance solutions for the universal turning and drilling of ISO-P steels.

The list of ISO-P steels is long and their diversity demands a wide range of high-performance tool solutions. Because, when low-carbon, ductile and high-alloy steel grades in numerous different hardnesses arrive on the turning machine, one solution is no longer suitable every time. That's why the turning specialists at CERATIZIT have repositioned their grades of indexable inserts and sharpened them to satisfy the requirements of ISO-P materials. The classic EcoCut has also been updated to perform the machining of challenging steels.

All-rounder for many applications

Be it drilling with a stationary or rotating tool, or turning of face, inside or outside profiles - the EcoCut is the Swiss army knife among cutting tools and the first choice for a wide range of applications. Alongside the EcoCut Mini and EcoCut ProfileMaster, EcoCut Classic tools are the multi-talented models in the series. Diameters between 8 and 32 mm can be machined with their indexable inserts, while setup times are reduced, and productivity levels simultaneously rise.

EcoCut tools have long been a classic in the CERATIZIT range. "But that doesn't mean we are resting on our laurels with the good characteristics of this series. On the contrary - the supplementary -P brings with it the update for machining ISO-P steels," explains Paul Höckberg, Product Manager Cutting Tools at CERATIZIT. "With this the user can either increase their cutting data and machine faster or, stick to their tried and tested parameters and benefit from longer tool lives!" Extensive tests have shown that the new EcoCut-P achieves 15% greater performance than the predecessor models.

DRAGONSKIN coating for ISO-P materials

"If you want optimum machining results in steel, you also need an optimised coating. That's why we have developed our special DRAGONSKIN coating for ISO-P materials, which is engineered to increase tool life and reduce machining time - thanks to an optimised layer structure," explains Stefan Karl, Product Manager Cutting Tools at CERATIZIT. The mechanical post-treatment induces a unique state of residual stress in the layer surface, which in turn increases process security. The DRAGONSKIN grade CTCP425-P with advanced AL2O3-TiN CVD coating is particularly impressive when uninterrupted cuts are required. It delivers excellent wear resistance even at increased cutting speeds. And when it comes to general steel machining with interrupted cutting, the AL2O3-TiN CVD

DRAGONSKIN grade CTCP435-P delivers the perfect solution. "Whenever poor machining conditions exist and, in all applications where a high degree of toughness is required, CTCP435-P comes to the fore with its stable processes," explains Stefan Karl.

Warning before it comes to wear

Another advantageous feature for EcoCut-P users is the new indexable insert indicator layer. It allows the user to see the degree of wear and indicates when it is time to replace it - because if wear is detected too late, the machining quality may already be severely impaired. "It doesn't bear thinking about. If the machine is driven to the limit despite this and the cutting insert then breaks, in the worst-case scenario the workpiece will already be damaged - with significant financial consequences. Now all it takes is one look at the special Dragonskin coating and stable, faultless processes are assured," enthuses Paul Höckberg.

Anyone concerned that the enhanced performance or longer service life will come at a high price can rest assured, as Paul Höckberg explains: "The new EcoCut-P indexable inserts deliver up to 15% higher performance in ISO-P steels, and yet we have kept the prices the same as their predecessors. This means our customers enjoy more performance and the indicator layer for better wear detection at no extra cost!"