CERATIZIT PolyClamp Verso gets a firm grip on every part

Anyone who regularly loads multi-axis machines with a wide variety of workpieces will be particularly appreciative of flexible part clamping. With its comprehensive workpiece clamping range, CERATIZIT has the solution to master every challenge. And now, even the trickiest of loading scenarios are overcome with ease thanks to the new PolyClamp Verso.

Struggling with long setup times and half-loaded machine tables results in losses - especially when it comes to the efficiency of production processes. If there is a need to perform machining from small batches right up to large batch sizes and in a wide variety of materials, it pays to opt for clamping systems that are flexible in use. "Productivity can frequently be increased by at least 30 percent simply through optimised workpiece handling during clamping and flexible retooling of the clamping technology, and in individual cases, this increase can even rise as high as 90 percent," explains Christoph Retter, Product Manager Workpiece Clamping at CERATIZIT. "Standardised solutions that are not tailored to a single workpiece often bring with them the happy added advantage of saving on procurement and storage costs," he adds.

Slim clamping jaws

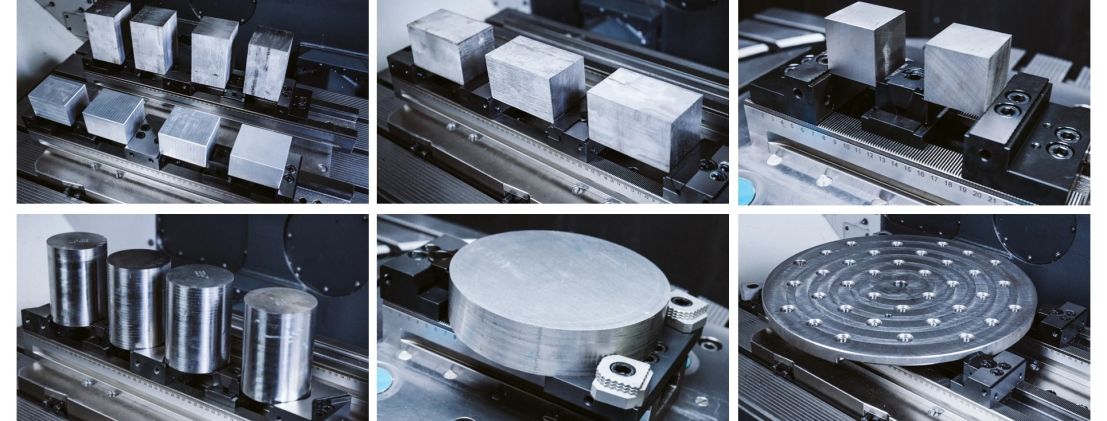

But what if there's a need to place particularly large or numerous smaller workpieces on the machine table? Thanks to universal multiple vices, powerful solutions exist here too - for example the new PolyClamp Verso from CERATIZIT. This model is particularly suitable for use in 3-, 4- or 5-axis machines, where it easily clamps all part variants.

The jaws have been slimmed down for this purpose. "Also advantageous with the new design is that even more jaws can now be clamped per base rail, meaning that more, larger unmachined, or finished parts can also be clamped," explains Christoph Retter. The scale lasered onto the centric vice is a further benefit when it comes to handling. It allows the jaws to be positioned evenly and precisely on the rail, in accordance with requirements.

The PolyClamp Verso is equipped with a quick jaw change system as standard. Using just two screws, the fixed and adjustable jaws can be released, removed upwards or repositioned. This massively reduces setup times, because each jaw can be individually removed without having to dismantle another one.

Individual solutions from the modular system

There are no limits when it comes to adapting the PolyClamp Verso to the respective machine situation. For example, several of the 300 to 900 mm base rails can be combined with corresponding connecting elements. And when selecting the clamping jaws, importance was also placed on maximum variety - with 24 variants available.

From clamping with a single vice, centric and multiple vice clamping, to clamping variants and zero point clamping systems - CERATIZIT delivers tension where it's needed in the machining industry. The particular focus with all variants is on keeping setup times to an absolute minimum. "When it comes to leaner production processes, this is often where the greatest potential lies. Although we never allow this to come at the detriment of precision or repeatability, of course. After all, we want to offer a high degree of tension, but not a high level of stress!", says Christoph Retter, emphasising the reliability and optimum force distribution of the CERATIZIT workpiece clamping systems.