Soraluce celebrates 60 years of state-of-the-art technology

Producing innovative pioneer engineering solutions to drive the technological change of companies operating in the machine tool sector, establishing new standards and addressing the challenges of the most demanding machining work, with high productivity and efficiency. This is the concept which machine tool manufacturer Soraluce has been perfecting for six decades since its beginnings in 1962, and which has earned the company its current status as world leader of milling, boring, multitasking and automation solutions.

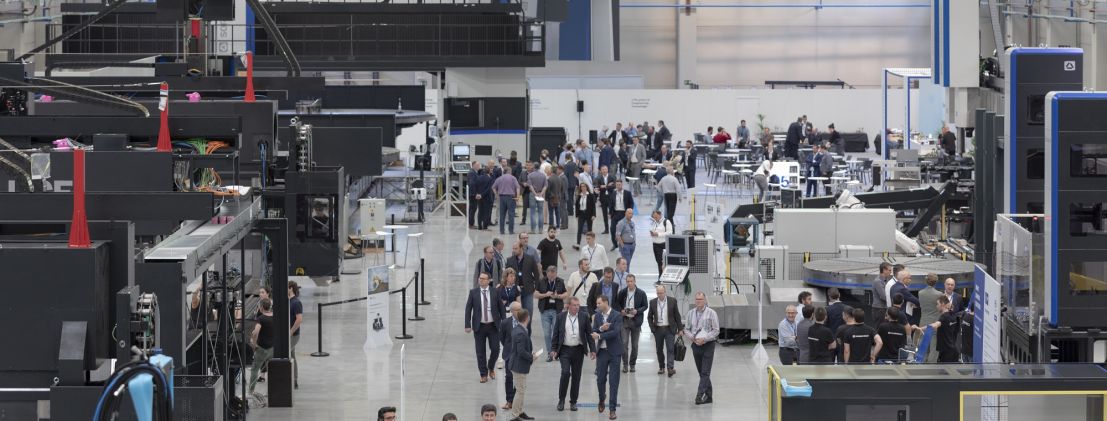

To commemorate its 60 years of state-of-the-art technology, the firm hosted another Soraluce Summit in mid-May at its Bergara plant. Over three days, the machine tool manufacturer showed the general public the very latest machinery, state-of-the-art technological solutions and cutting-edge Digital Services. The benefits of which were made clear with demonstrations and live machining.

Leader range

Higher production rates, greater accuracy, higher efficiency, better performance, greater user-friendliness, improvements to ergonomics, safety and higher profitability, lowering cycle times, downtime, consumption and emissions. This is the premise on which Soraluce has been providing the machine tool sector with innovative solutions for the last 60 years. At the open-day event, among other new features, the company presented a new large-format multitasking machine integrating milling processes with turning processes with a high automation capacity. The machine is built for the German company Krones, a world leader in production lines for the food and beverage industry. The machine features bridge-type moving table architecture, and has two rotary-travelling milling/turning tables, diameter 6,000 mm, tilt 7,100 mm, with up to 40 Tn parts capacity. Furthermore, it has a range of milling and turning heads and robotized storage with 500 tools.

Smart technology

On a guided tour, Soraluce showcased its latest progress and milling, boring, multitasking and automation projects, along with new smart damping solutions to boost the removal of chips during machining. Those at the event where able to study all these technologies first-hand in live demonstrations. In this regard, the Soraluce Summit presented its active damping system DAS, a smart system which oversees the machining process and chooses the best technological alternative to eliminate vibration, and its active damping facility DWS (Dynamic Workpiece Stabiliser) which eliminates chatter or vibration when flexible parts are being machined, and which won the 2020 Quality Innovation of the Year award.

Advanced digital services

In addition to its new features in terms of machinery and technological solutions, the firm also demonstrated its innovation in industrial digitalisation, all produced at the Soraluce Software Factory, an in-house system developing advanced software solutions, the latest technology and digital services. Here Soraluce showcased some of the advanced digital services that are helping step up the pace of the digital transformation of businesses operating in the sector, such as the Autocheck system producing an automatic diagnosis of machine status, the FactoryConnect solution for plant digitalisation; the EMaintain tool which automates and digitalises maintenance processes, and the new functions of the Smart HMI interface, boosting the efficiency of manufacturing processes. To complete the range of new digital services, for the first time the machine tool manufacturer presented the general public its integral monitoring platform “My Soraluce”, for better monitoring of current machine status. A new system which, as Soraluce's head of Services and Solutions Alejandro Martínez explains, "provides customers with direct access to all the machine's information, enabling them to check its current status at any time from any location, making the process easier, faster and clearer."