Soraluce unveils the future of machining solutions #MadeForYOU live at EMO

Higher production rates, greater accuracy, improved efficiency, better performance, easier to use, improved ergonomics, safety and profitability; all while reducing cutting cycle times, shutdown times, consumption and emissions. This is the #MadeForYOU concept of the fully customized range of machinery, technologies and services that Soraluce, the machine-tool manufacturer, will present at the EMO Milano 2021, the world machine tool trade show, to be held in the Italian city from 4 to 9 October.

Soraluce, a leader in the development of milling, boring and multitasking solutions, will showcase an innovative proposal at Stand D06, one of the main stands located at the start of Pavilion 3 at the fair. The proposal will cover three areas: state-of-the-art machinery –Leading Generation-, cutting-edge technological solutions -Smart Technology- and advanced Digital Services. Visitors to the fair will be able to discover the benefits of the live continuous machining and demonstrations throughout the event.

Leading Generation

The European manufacturer will take its latest developments in milling, boring and vertical turning machines, multitasking solutions, along with automation lines and “best in class” services, to the Milan event. It is the most comprehensive and advanced machinery range on the market, which is also designed to be customized to each client’s specific requirements.

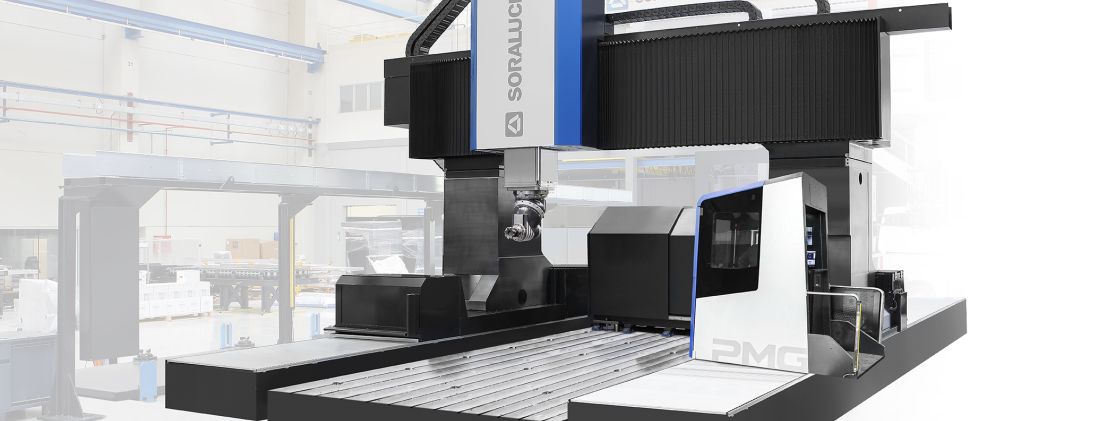

One of the Soraluce highlights at the event will be the SORALUCE PMG portal gantry milling machine, to be presented on the Italian market for the first time. The model has a longitudinal traverse of 10,000 mm, a cross traverse of 4,000 mm and a vertical traverse of 1,500 mm, fitted with a stepless universal head of 0.001º x 0.001º at 7,000 rpm.

Soraluce, the trail-blazer in the use of linear guiding systems, has applied all its expertise to the development of these new portal machines. They combine the linear guiding technology with the damping systems by means of incorporating solutions such as DAS® (Patented), an active damping system to eliminate chatter and exclusive to Soraluce.

The result is highly productive machines, with great precision, and that are dynamic, stable during machining and reliable as regards availability.

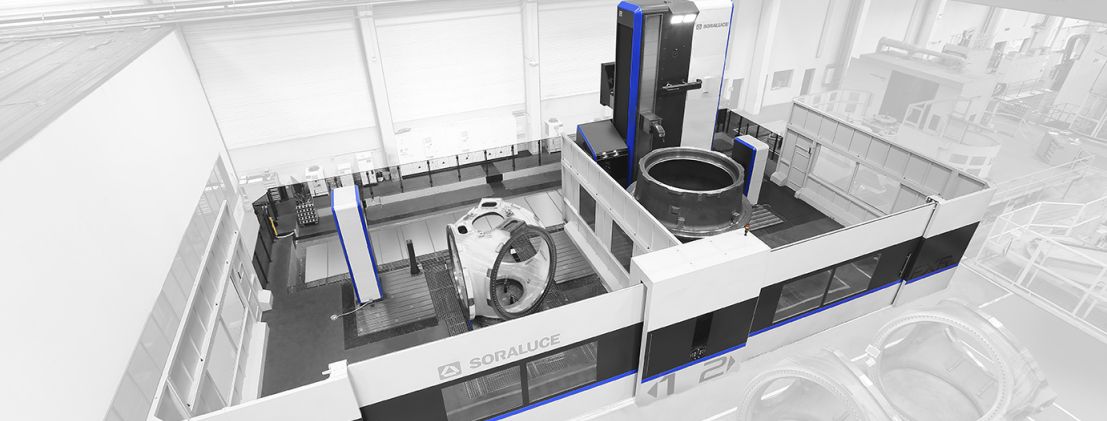

In keeping with the #MadeForYOU philosophy, the new portal model can be customized to meet each client’s requirements, where the work areas can be configured to optimize productivity, by minimizing shutdowns while fitting the workpiece, or to increase the versatility and flexibility of the machine, by incorporating the multitask feature with rotary tables for milling and turning. Its options include milling and turning heads, and tool storage.

The machine-tool manufacturer assembles this type of machines at the state-of-the-art Soraluce Portal Factory. The company has invested €9 million in the facilities to create a modern and advanced manufacturing center, that is one-of-a-kind in its category in the world, and dedicated to the manufacturing of portal machines.

Along with the latest developments in the portal machinery range, Soraluce professionals will show the visitors to the fair the company’s whole range of milling machines, multitasking solutions and automation lines. The visitors will also have the chance to learn about the portfolio of “best in class” services that increase the precision, productivity and profitability levels of machining.

Smart Technology

Soraluce continues to consolidate its great commitment to technology, by developing high value-added services and offering expert advice to its clients. Thus, during the fair, Soraluce will showcase smart damping solutions to increase stock removal during the machining. The solutions have been developed thanks to the company’s high technical expertise and its knowledge of engineering applied to manufacturing solutions. The visitors will also have the chance to find out about these technologies for themselves during the live demonstrations.

The manufacturer has developed different systems to eliminate chatter, thus increasing the cutting capacity of the equipment and the efficiency of the machining processes.

On the one hand, Soraluce will showcase its renowned active damping system, DAS®, the smart system that oversees the machining process and selects the best technological alternative to eliminate chatter. Fitted with a very simple interface, this solution allows the evolution of the process to be controlled, by providing comprehensive information on the chatter, the vibration level and the technologies used to suppress it; such as the active damping of the ram, the tuning of the optimum spindle speed of the tool and the harmonic oscillation of the spindle speed. “This system allows productivity to be increased by up to 300%, maintain 100% cutting capacity throughout the whole of the machine’s work volume, cut machining times by up to 45%, improve the surface quality of the machined workpieces, increase the tools’ useful life and the long-term precision of the machine by reducing the wear of the internal components,” explained Xabier Mendizabal, Soraluce’s R&D Director.

On the other hand, there will also be a live presentation of the DWS (Dynamic Workpiece Stabilizer) system, an active damping device that eliminates the chatter that is usually generated when machining flexible parts. This patented system, which was the winner of the Prize award in the International Quality Innovation of the Year 2020 competition, provides an effective solution for the problems associated with machining slim-format parts and is an improvement on traditional alternatives. One its main benefits is a better surface finish in areas where the workpiece is more flexible, and the chance to boost productivity thanks to in-depth passes with no vibration problems. Its user friendliness, its adaptability to different workpieces and its portability are some of the other advantages of the device.

Digital Services

Competitiveness, efficiency and availability are only just some of the advantages that digitalization offers for industrial manufacturing processes. Therefore, in addition to its latest development in machinery and technological solutions, Soraluce will also present its innovations in the field of industrial digitalization, fully developed at the Soraluce Software Factory, the center for the advanced development of Soraluce’s software solutions, advanced technologies and digital services.

In this regard, Soraluce provides advanced Digital Services, based on the Soraluce comprehensive monitoring platform that can be seen at EMO with live demonstrations. Some of those developments are: Autocheck –self-diagnosis of machine status comparing with Fingerprint benchmark parameters -, FactoryConnect -plant digitization and integrations with the Corporate Management Systems-, EMaintain -automation and digitization of the maintenance processes. Soraluce uses those services to help its clients to accelerate their digital transformation, by optimizing the performance of the machines.

On the other hand, Soraluce will present the Smart HMI at the EMO in Milan. The smart interface has new features to increase the efficiency of the manufacturing processes, thus providing great ergonomics and ease of use. Developed at the Soraluce Software Factory, Smart HMI incorporates new Apps, which are now smarter and more personal, where users can access new features in a unique work environment. One of the most notable applicable applications that Soraluce has added to its Smart HMI is the ability to edit programs simultaneously to the manufacturing process. This means that a manufacturing program can be run in the control zone, at the same time that another is edited in the new expanded section.

Last but not least regarding innovations in digital services, the machine-tool manufacturer will launch as a world-first the “My SORALUCE” platform, a new free portal for clients to enable greater control of the current status of the machine. As Alejandro Martinez, Soraluce’s Director of Services and Solutions, explained, “this new system provides clients with direct access to all the information relating the machine, which allows them to control the current status of their machine at any time and from anywhere. More user-friendly, quicker and clearer.”