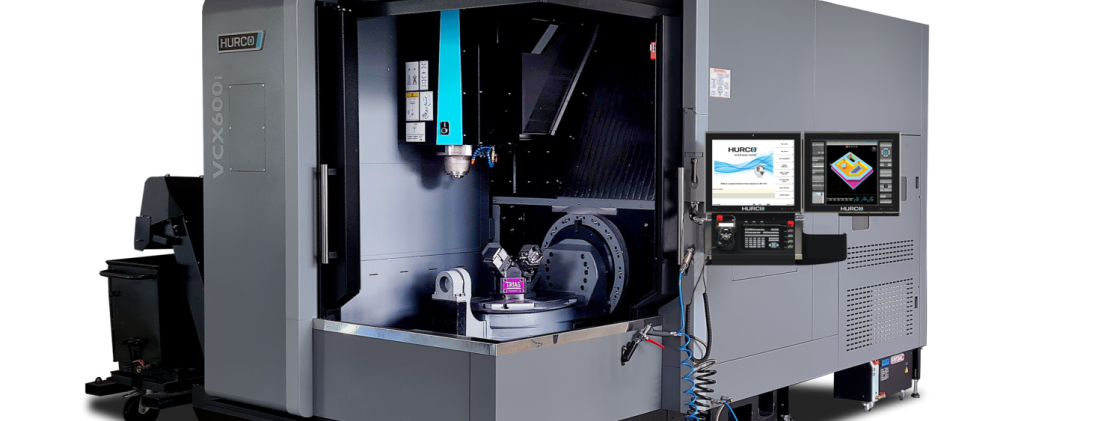

Hurco has developed a new machining center whose design is based on the complete five-axis know-how of the machine builder. The five-axis VCX600i XP offers increased productivity, stability and accuracy compared to the company's previous five-axis models. The machining center is intended for manufacturers who only machine complex, medium-sized workpieces.

To increase productivity, stability and accuracy, Hurco has brought together all available know-how in the new five-axis VCX600i XP. The machining center has an extremely stable design. For example, the swivel table is robustly embedded in the machine frame on one side. This not only gives more stability, but also creates more space in the machine, which has a positive effect as the workpiece size or mass increases. A movable column ensures a higher mechanical accuracy. The swivel table is driven by torque drives, so that both turning and swiveling can be performed simultaneously and dynamically.

Accurate and dynamic

Hurco has equipped the machining center with a 16 kW strong SK-40 spindle with a torque of 102 Nm and a maximum speed of 12,000 min-1. The tool magazine offers space for 40 tools. The roof of the machine can be opened separately for optimal access to the working area through crane loading. This means that even larger workpieces can be loaded efficiently and flexibly. Sebastian Herr, Head of Application Technology at Hurco: “The VCX600i XP is designed for precise and dynamic operations. When developing the five-axis machine, we took into account that the demand for more complex and precise components will only increase in the future. So the machine is prepared for that."