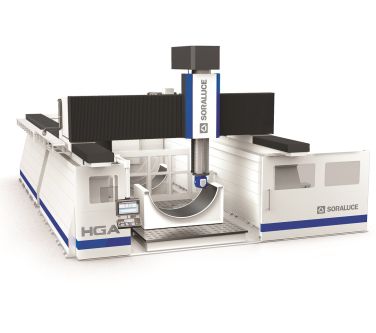

Soraluce Unveils Dynamic 'High Rail' Gantry Milling Machines

Soraluce has announced the new High Rail gantry milling machines. These state-of-the-art gantry machines merge precision, dynamics, and efficiency, making them ideally suited for industries demanding the highest standards in production processes.

The Dynamic Line from Soraluce encompasses three machine models, tailored for applications in sectors such as aerospace, mold making, and machine construction. They are adaptable to accommodate various milling heads, including five-axis contour milling heads or high-torque heads for heavy-duty milling. The new line is further customizable with solutions for specific materials, ranging from composites and alloys to steel-based components. This versatility ensures seamless processing of intricate and complex shapes.

Dynamic, Precise, and Efficient

The new gantry milling machines of the Dynamic Line from Soraluce feature three primary characteristics. First, they are designed for high dynamics. Thanks to the High Dynamics feature, they can achieve high speeds. With travel speeds up to 60,000 mm/min and accelerations up to 4 m/s², these machines are built for maximum productivity. This is enhanced by the state-of-the-art five-axis contour milling heads, boasting speeds up to 30,000 RPM. According to Soraluce, however, it's not just about achieving high speeds. The challenge is to pair this speed with high precision. Only then can large workpieces with complex geometries be optimally machined. To ensure this high level of precision, Soraluce opts for a construction design with high thermal stability. This ensures consistent performance, even amid fluctuating temperatures and heavy-duty machining tasks. Additionally, the Dynamic Line is equipped with calibrated kinematics for even further enhanced precision. Every movement is precisely controlled and calculated.

Dynamic Yet Powerful

The new gantry milling machines from the Dynamic Line are not only accurate and dynamic but also possess sufficient power for heavy-duty milling. A key feature enabling this capability is the robust mechanical heads, designed to deliver powers up to 73 kW. Moreover, Soraluce offers a wide range of mechanical five-axis contour heads with high torque, reaching up to 2,000 Nm. To increase stability and performance, Soraluce has integrated its well-known intelligent damping solutions, DAS+ and DWS. Along with a robust, cast-iron frame, these features minimize vibrations, even in the most demanding work environments.

Clean and Safe

In response to the desires of many machinists for a clean working environment, Soraluce has equipped the new machine line with extensive splash guards to maintain a clean and safe working environment. Moreover, various dust extraction systems, both within the machine workspace and integrated into the heads, ensure the removal of dust and debris generated during the machining process, maintaining optimal cleanliness during operation.

"We are thrilled to introduce the Soraluce High Rail Gantry Machines," says Oier Elguezabal, Global Business Development Director at Soraluce. "These machines embody our commitment to innovation, precision, and efficiency, allowing manufacturers to achieve a high level of productivity and quality in their operations."