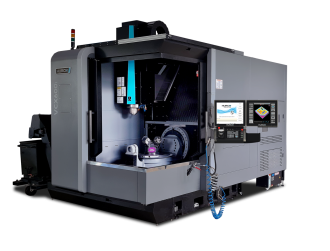

Produce parts faster with the DATRON MXCube high-speed machiningcenter

DATRON announced the release of the newest addition to its family of easy-to-use high-speed CNC Machining systems, the DATRON MXCube. The MXCube allows manufacturers to produce parts faster and easier and is ideal for milling precision high-tolerance parts. The MXCube takes up very little floor space relative to its large machining area. The results are a rigid machine with a high-speed spindle that is tailor-made for modern HSC strategies while ensuring a high material removal rate and extreme precision.

Featuring a reinforced rigid steel frame and a mineral cast machine table, the MXCube’s rigidity allows for higher loads of HSC milling while offering exceptional vibration dampening. The machine is perfectly suited for mold making, research and development, micromachining, extreme precision, and more. DATRON’s newest machine features a drive train made entirely of steel that operates on 25mm ball screws. In addition, all axes are equipped with absolute linear scales which allow the extremely precise MXCube to achieve tolerances in the microns. The MXCube also comes equipped with a 10HP spindle producing 34,000 RPM which it uses to traverse the 1,040mm x 850mm x 270 machining area.

Available Options

A standard feature for the DATRON MXCube is its 60-station automatic tool changer which is externally located and shielded from material debris and dust. The tool changer includes a five-station tool holder that can be loaded/unloaded while the machine is in operation. Another standard feature is a sliding cabin door that was specifically designed for integration with automation in mind. Also, an easily attached conveyor-driven chip management system is available for the MXCube. Other innovations include integrated LED machine status lighting, coolant level monitoring, air level monitoring, and space for two internally stored 9-liter coolant containers for minimum quantity coolant.

Look & Feel

The DATRON MXCube also comes with the standard features that have set the rest of the DATRON machines apart from traditional machining centers. The Renishaw TP-20 probe increases machine accuracy while a magnetic breakaway tip helps crash avoidance. Also included is the intuitive touch screen operation terminal that has been consistently praised by operators of all experience levels for its ease of use and familiar swipe and tap gestures. DATRON’s newest Red Dot Award-winning CNC machine was designed from the ground up to deliver a productive machining solution that improves and accelerates workflow through a simple and clean operation that virtually eliminates post-processing.

The MXCube will slot into the top end of the current DATRON machine lineup as an extremely precise and flexible high-end offering. Its envisioned customer base is companies that operate in low volume / high mix industrial environments such as product development, aerospace, mold making, micromachining, medical, and more.