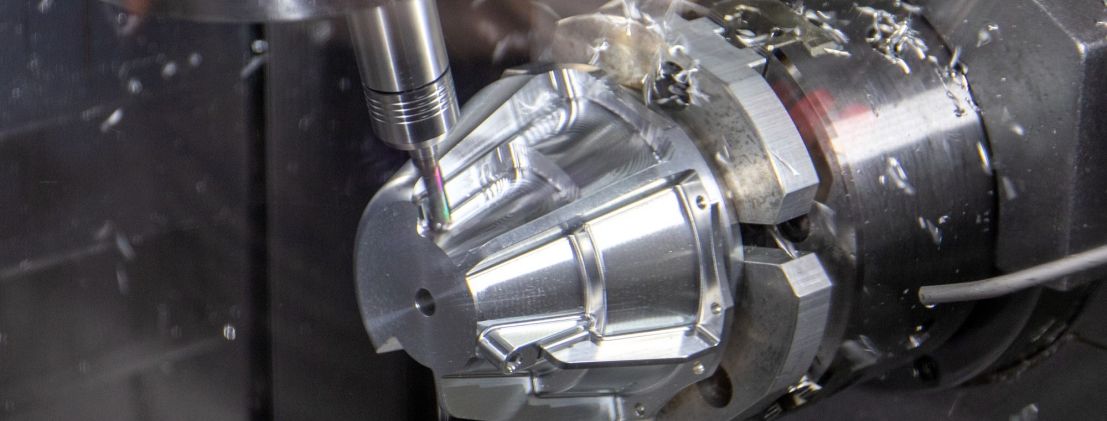

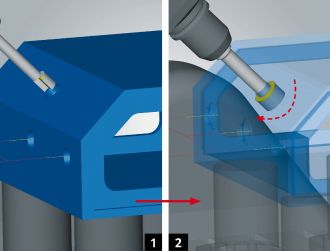

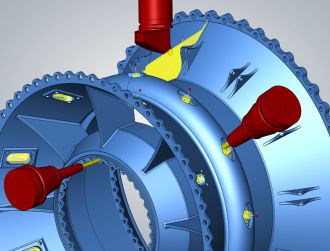

OPEN MIND draws a positive conclusion after its appearance at EMO in Hanover. The live demonstration of the turning and milling production of a workpiece inspired by aerospace components on the Mazak INTEGREX i-100H S turning and milling center attracted a lot of attention. The many components on display from a wide range of industries and applications demonstrated the breadth of hyperMILL technologies and sparked discussions – including about automation in CAM programming.

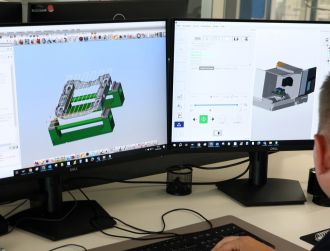

Specific machining strategies, as demonstrated by the hyperMILL TURNING Solutions, were often the starting point for conversation, but visitors to the booth were also very interested in advanced technologies such as the hyperMILL AUTOMATION Center and the use of digital twins with hyperMILL VIRTUAL Machining. Many users are looking for ways to further optimize their processes and were impressed by these two technology packages from the CAD/CAM suite.

Connected processes

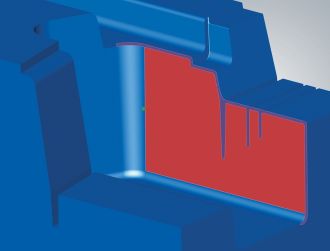

"Smart, connected, and integrated processes continue to be a very important topic for our users, as this is where digitalization unfolds its cost- and time-saving potential," explains Claudio Jorio, Sales Director DACH & Global Reseller at OPEN MIND Technologies AG. With hyperMILL and Hummingbird-MES, we are ideally positioned to offer companies innovative solutions for networked process environments that increase production efficiency.

At four workstations, visitors could experience demonstrations of hyperMILL functionalities and the Hummingbird Manufacturing Execution System. OPEN MIND positioned its hyperMILL and Hummingbird-MES as central components for the digitalization of process chains in the context of connected manufacturing