OPEN MIND and DAISHIN SEIKI CORPORATION celebrate 15 years of partnership

DAISHIN SEIKI CORPORATION and OPEN MIND Technologies have enjoyed a fruitful relationship for 15 years, working together to solve machining challenges. A motorcycle helmet programmed and milled by DAISHIN acts as OPEN MIND’s central image motif in its marketing materials (key visual). The helmet was a demonstration of the Japanese contract manufacturer’s expertise in using the 5-axis technologies that the hyperMILL CAD/CAM suite can offer. This year, the motorcycle helmet – which has now become a YouTube celebrity in its own right with more than 5.2 million views – is being redesigned. The helmet will continue to be the reference component people associate with hyperMILL.

“CEO of DAISHIN SEIKI CORPORATION Ryosuke Omachi’s ingenious idea to mill a motorcycle helmet from a solid to demonstrate his company’s 5-axis machining expertise has been attracting tech-savvy visitors to our booths for years. They even have their picture taken with the YouTube star,” reveals Volker Nesenhöner, CEO of OPEN MIND Technologies AG. “We are delighted to be able to use this and other demonstration parts from DAISHIN, and our marketing team has now given this famous eye-catcher a modern redesign to mark our 15-year collaboration. DAISHIN is a true power user and our development department is greatly appreciative of the valuable feedback this customer provides.”

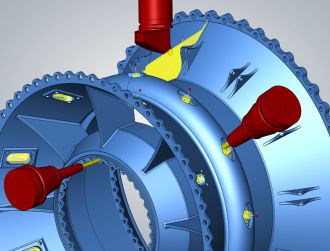

Manufacturer for the motorsport industry

DAISHIN is a leading supplier of prototypes for the motorsport industry, among others. The company has also sworn by the CAD/CAM solution and its world-leading 5-axis technology ever since it acquired a customer business that used hyperMILL for programming back in 2008. Motorsports enthusiast Ryosuke Omachi came up with the enduro helmet idea while looking for an almost spherical object to push his new 5-axis milling center from DMG MORI to the limit. The popular YouTube video shows how a 3.6 kg helmet was milled from a 120 kg aluminium block (A7N01-T6).

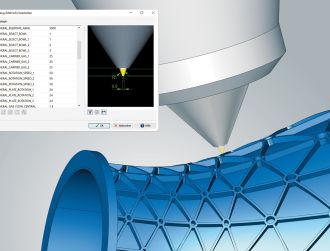

Showcase for 5-axis machining

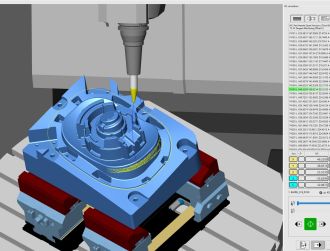

OPEN MIND is staying true to the showcase for 5-axis machining and has modernized how the helmet is depicted. The key visual now shows CAD mesh, CAM toolpaths, and the finished component in one image composition.

“Generating the NC code with hyperMILL was a key factor in creating this unique reference component. hyperMILL is easy to use and has great depth with excellent collision avoidance thanks to its powerful strategies. A machining video getting more than five million views is sensational and a testament to the technical achievement that comes from the collaboration between DAISHIN and OPEN MIND,” says Omachi. “The milled helmet still endures as a shining example, and I’m happy that this symbol is now getting a fresh, modern redesign. The world of manufacturing is changing faster and faster, but the relationship between DAISHIN and OPEN MIND, which today can be described as familial, remains unchanged and will continue into the future.”