The CNC Milled Nutcracker from OPEN MIND is here

In keeping with the Christmas season and its traditions, OPEN MIND is showing how a replica of a famous nutcracker from the Erzgebirge - a region in East Germany - is milled from aluminum. The example demonstrates an end-to-end digital process chain and efficient 5-axis machining with hyperMILL.

Together with EMUGE-FRANKEN, CAD/CAM developer OPEN MIND set itself a task: To digitally reproduce a 40-centimetre tall nutcracker as accurately as possible and mill it from aluminum as efficiently as possible. The traditional Seiffener Volkskunst provided the wooden figure, which was handcrafted in around 150 steps and consists of around thirty individual parts.

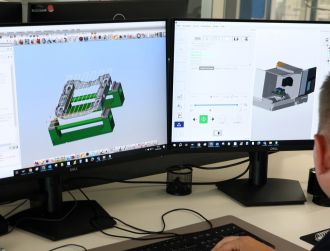

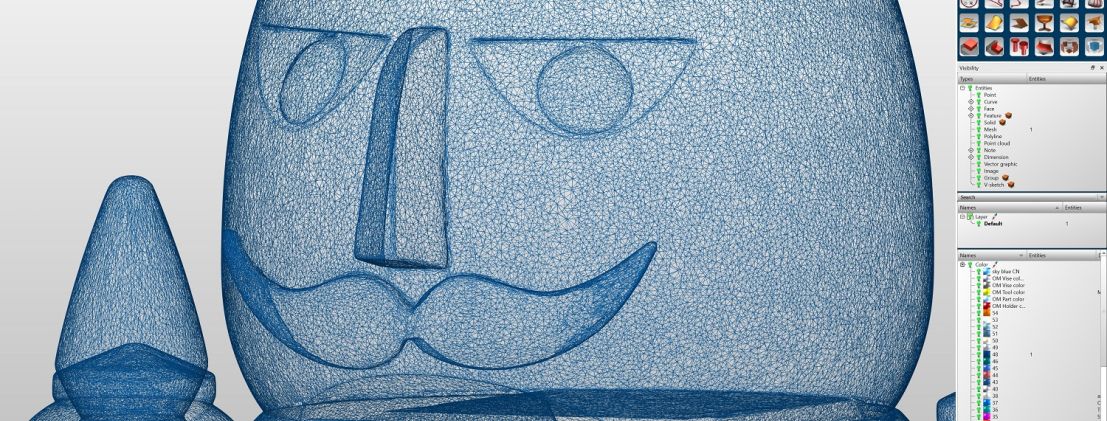

From scan to surface model

OPEN MIND turned to WESTCAM for the 3D scan of the nutcracker. The Austrian partner is not only characterized by its hyperMILL expertise, but it also has extensive know-how in 3D measurement technology. The scan resulted in a high-resolution mesh model consisting of 1.2 million triangles. At OPEN MIND, a surface-based 3D model was created using the hyperMILL CAD/CAM solution and designed completely parametrically. The latter's advantage is that production-related changes to the model can be made very easily afterwards. For production, the nutcracker model was divided into the upper part, legs, arms and lever, which were pinned and glued together after completion.

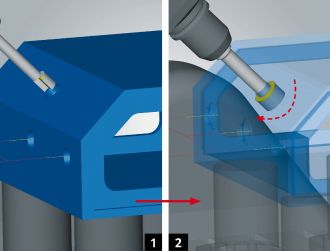

Roughing and rest material machining

Production was carried out at FRANKEN's Rückersdorf application center on a Hermle C32 machining center in a single clamping operation using 5-axis and 5-axis simultaneous processes. This allowed the surfaces to be machined continuously without segmentation. The opening cut for the large central pocket of the upper body was efficiently achieved using 5-axis helical drilling, which enables a particularly high level of material removal and is also gentler on the tool than a helical plunging movement. Strategies from the hyperMILL MAXX Machining high-performance package were used to optimize roughing operations. The 5-axis rest machining function then ensured that the roughing was completed safely and efficiently. The new EvoGrip centric clamp from EMUGE was used for workpiece clamping. With its modular and slim system design, reliable clamping was guaranteed.

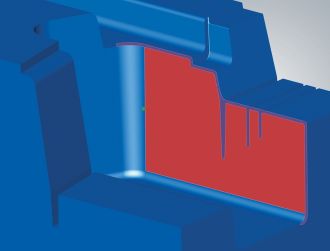

Finishing with Circle Segment End Mill

The ‘high-precision surface’ mode was used for finishing, whereby hyperMILL generates tool paths on the actual CAD surfaces and not on a calculation model. The large surfaces of the nutcracker which are curved in two directions, lent themselves to the use of FRANKEN's circle segment end mill in various shapes. For this application, taper and teardrop shape tools with cutting radii from 200mm to 1000mm were used. These tools, also known as barrel cutters, enable particularly efficient production of high-quality surfaces despite the large in-feeds or large step-over line increments. hyperMILL offers optimum control of the cutting-edge area of circle segment cutters.

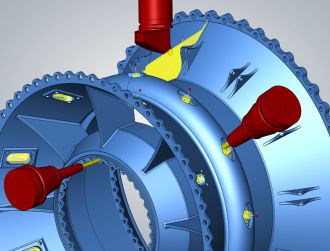

Simulation and optimization in the virtual machine

"In the nutcracker machining example, we had the problem that the dimensions of the part were too large for the work area of the machine - a challenge that many manufacturers have already faced," explains Michael Förster, Senior Product Marketing Manager at OPEN MIND Technologies AG. "What would normally require many manual adjustments and individual simulations to avoid travel limitations and find safe tilt positions can now be implemented quickly and reliably thanks to the virtual machine and NC code-based simulation."

The hyperMILL VIRTUAL Machining package includes an optimizer that perfectly adapts the connecting movements between the individual milling operations to the kinematics of the machine and can therefore solve limit switch problems. Communication between the milling center and the software, which contains a digital twin of the machine, allows precise machining-based simulation of the actual NC code.