OPEN MIND hyperMILL Achieves Success with Suppliers to the Semiconductor Industry

OPEN MIND is experiencing strong demand for its hyperMILL CAD/CAM suite from suppliers to the semiconductor industry. The industry is known for its very high-quality requirements with high-mix, low-volume production. Users therefore rely on innovative high-end solutions for reliable generation and simulation of NC programs. Plant designers, special machinery builders, and their specialized manufacturers stress to OPEN MIND that high-precision surfaces, programming automations, and reliable postprocessor technology are the key decisive factors for choosing hyperMILL.

Internationally active companies in the semiconductor industry have been relying on the CAD/CAM technologies of hyperMILL for some time now. Examples of this positive and trusting cooperation can be found on the OPEN MIND website: BKB Precision, AAE, NDK Paragon, and RE Thompson are just a small selection of the software developer’s customers that are suppliers to the semiconductor industry.

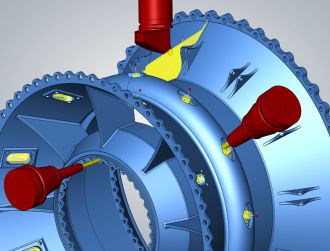

The machines and devices used in modern chip manufacturing can be divided into three main categories: wafer production, assembly equipment, and testing equipment. The enormous variety of parts ranges from prototype construction to small series and series production. Components such as vacuum chambers, wafer handling components, or distributors made of special plastic place the most varied demands on the CAM system in terms of material and geometry diversity. Being able to act with maximum flexibility, but at the same time reliably in production, is enormously important for many manufacturers in the industry.

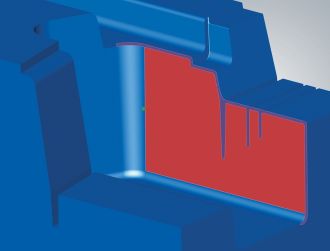

Perfect Surfaces

Similar to the medical technology and aerospace industry, cleanliness, accuracy, and perfect surfaces in high gloss quality are the most obvious requirements in the semiconductor industry. The components are often complex, for example, prismatic and with many holes and pockets. Here, feature and macro technology make programming easier, and OPEN MIND’s leading role in 5-axis machining also plays a part. “hyperMILL allows us to generate 5-axis NC programs quickly and easily. We like the fact that the software offers different tilt strategies for 3+2 and 5-axis simultaneous machining – and also a range of options with the 5-axis rework machining strategy. In addition, hyperMILL enables set-ups for milling and turning on multitasking machines,” says Hein Raaijmakers, CAM programmer at AAE B.V.

Berrie van de Burgt, Sales Director at BKB Precision and a specialist in machining high-performance plastics, explains: “Offline programming and simulation are critical for our “right-first-time” principle, especially when we’re machining expensive materials such as PEEK. The milling strategies are also very easy to adapt to the different materials. This helps us reduce errors and scrap.”

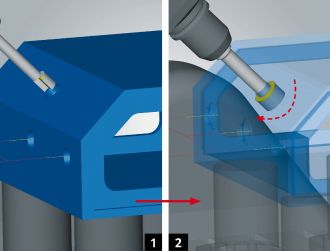

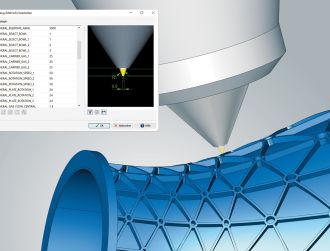

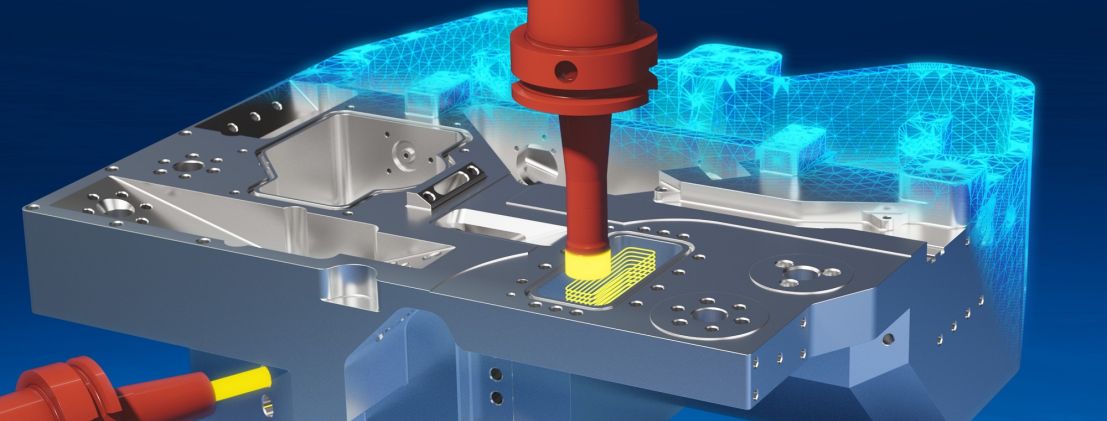

Simulation with Virtual Machine

The capabilities of hyperMILL and the virtual machine in the area of simulation with digital twins and the related postprocessor technology are particularly appreciated in the industry. NC codes must be generated quickly and reliably, especially in the high-mix, low-volume production environment. This reliability of the NC code is a decisive criterion when choosing the right CAM system. Berrie van de Burgt explains: “hyperMILL is so well integrated into our production process that we don’t even think about the benefits anymore. The fact that we produce 24/7 with only one day shift always impresses our customers. We have so much confidence in hyperMILL that we integrate new production series directly into our 24/7 production cycle, whereas other manufacturers tend to limit initial production to manned shifts.”