OPEN MIND drives complete machining at Zeltwanger

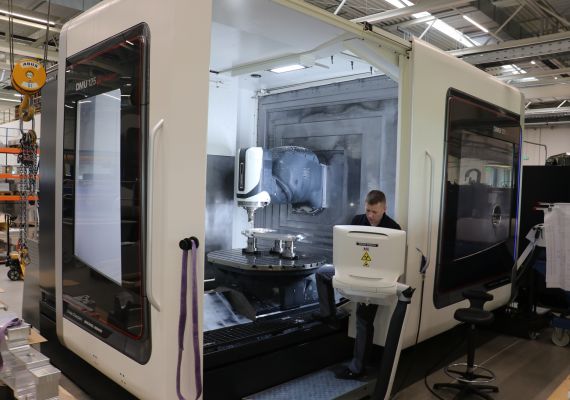

Zeltwanger Maschinenbau GmbH positions itself as a service provider for complex, high quality component machining across the semiconductor, automotive, medical technology and micro automation sectors. The company leverages hyperMILL MAXX Machining, hyperMILL TURNING Solutions and hyperMILL VIRTUAL Machining to accelerate programming, raise process reliability and validate NC code. Zeltwanger also collaborates as a beta tester to help expand these capabilities.

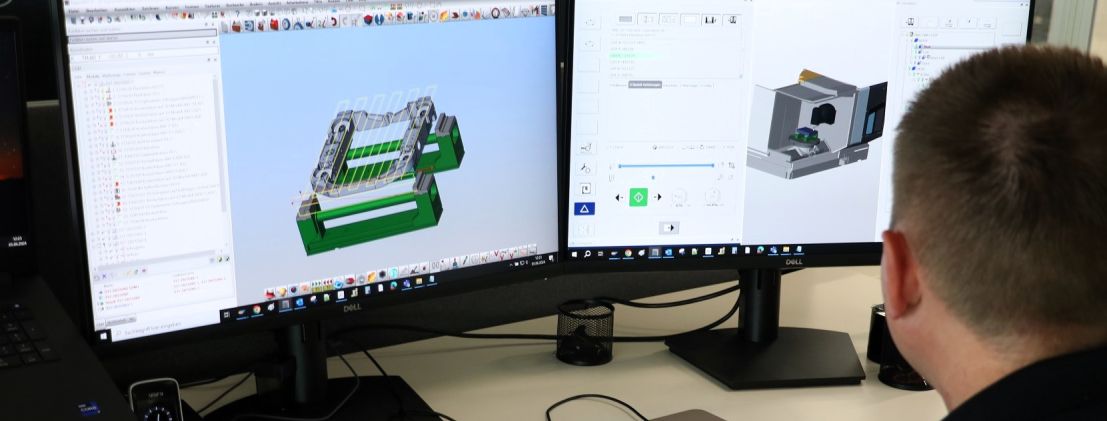

Zeltwanger serves demanding customers with wide ranging part portfolios. For a semiconductor customer focused on laser technology, the contract manufacturer supplies components that require the highest precision, from pin sized stainless steel parts to 250 kg workpieces produced from three ton aluminum blocks. “µm tolerances are the order of the day for us,” says Wolfgang Pfeiffer, Head of CAM Programming. Batch sizes range from one piece to series runs of about 500 units, which means the team must create between 20 and 60 executable, reliable NC programs each week. To meet this workload the company programs in two shifts and relies on CAM software that supports fast, dependable workflows. Zeltwanger has used hyperMILL since 2008. The ten person CAM team has expanded its setup with optional modules including TURNING Solutions and VIRTUAL Machining.

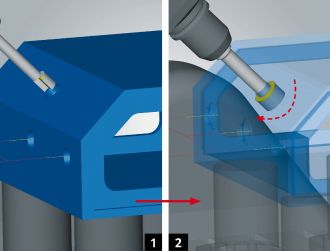

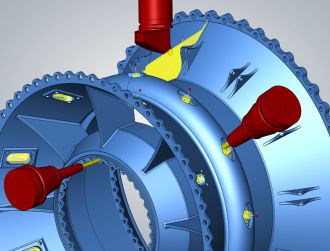

Turn milling enables complete machining

Zeltwanger applies turn mill centers to reduce set ups and stabilize accuracy. Combining turning and milling on a single machine allows many parts to be completed in one clamping. This removes downtime due to machine changes and prevents reclamping errors that can compromise tight tolerances. Programming such centers is demanding, so the team standardized on hyperMILL TURNING Solutions together with the TURN MILL Machining module. According to Pfeiffer, the turning functions align closely with familiar milling workflows, which made onboarding straightforward for experienced programmers. The result is reliable toolpaths and a dependable simulation environment for collision prone machines. For milling and turning centers, the hyperMILL MILL TURN Machining module allows high performance milling strategies to be combined with turning operations. This supports complete machining with an emphasis on efficiency, precision and process safety across varying batch sizes.

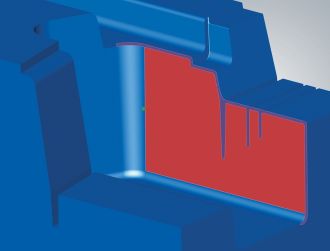

Virtual machining secures NC reliability

Process reliability is reinforced with hyperMILL VIRTUAL Machining. NC code is generated, optimized and simulated against the real machine environment so that milling, turning and hybrid machining can be validated before the program reaches the shop floor. “The software only provides access to successfully tested and, therefore, safe, collision free programs,” says Pfeiffer. Zeltwanger uses this module intensively and contributes as a beta tester, with a particular focus on mill turning where OPEN MIND continues to expand the use of virtual machines. This approach supports the company’s weekly output of 20 to 60 programs by filtering out collision risks early, standardizing postprocessed NC for complex equipment and maintaining accuracy on both small pin sized parts and heavy 250 kg components. The combined setup of turn milling and virtual machining helps the ten person CAM team sustain µm level tolerances while meeting two shift programming demands.

Zeltwanger’s collaboration around turn mill strategies and virtual machining underpins consistent quality for customers in semiconductor, automotive, medical technology and micro automation.