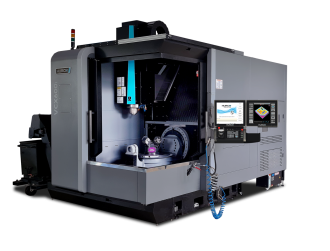

F. Zimmermann Offers Efficient Thermosymmetric Machine Designs for Heavy Machining

With the FZU/FZP42 machine line, F. Zimmermann offers efficient 5-axis portal milling machines for heavy machining. Its specific feature is a thermo-symmetrical design incorporating a centrally guided Z-slide. This particular construction, as well as the guide layout, increase its stability, while also saving weight at the same time – resulting in a more dynamic, productive and energy-efficient machine.

„We develop suitable machine designs for light processing, such as composite materials or aluminum, as well as for highly dynamic heavy machining“, reports Rüdiger Hellwig, head of sales at F. Zimmermann GmbH. While further developing their machine portfolio, in the last several months, heavy machining has gained an even higher significance. At the same time, we are at the cutting edge in this segment, explains Frieder Gänzle, CEO: “We focus less on classic heavy machining, using large tools and high material removal rates per cut. Instead, the FZU/FZP42 model range provides tool and mold makers with a 5-axis system for complex components, which enables dynamic milling of free-form surfaces.”

Dynamic heavy machining? Precisely this is the challenge. Because the more difficult it is to process the materials, the higher the requirements to the rigidity of the machine. Weighting in at several tons, thus, the machines are quite „massive”. How can this massive design deliver great dynamics, so that users can work even more productively? “Our machines mill out contours with a maximum speed of 60 m/min and may accelerate with 3 m/s2 if needed. “This resembles a motorcyclist, accelerating in a curve to pass it more dynamically”, compares Mr. Hellwig. Despite the acceleration, the machines must be able to achieve very high accuracy as well as high-quality surfaces. “This connection of dynamics and heavy machining may be compared to a truck, loaded with stones, performing in a formula 1 race”, states the head of sales.

Thermo-symmetry for more precision

To achieve this, Zimmermann is setting up their complete machine portfolio thermo(load)-symmetrically. This is because changing ambient temperatures, as well as processing temperatures, inevitably influence machine geometry featuring a portal design. The idea behind a thermo-symmetrical design is based on the ability to substantially absorb incurring thermal influences, achieved by the design of the machine structure itself. Considering this, Zimmermann appropriately designed and intelligently arranged structure and drive unit components, guides, as well as other components responsible for accuracy, for all machines in the further developed portfolio. This way, the structure may expand in directions that are non-critical.

The centrally guided Z-slide of the portal in double-bridge construction has a large cross section which makes it especially stable. Using this design, Zimmermann achieves a very high rigidity. Since there is no possible one-sided temperature rise, accuracy is greatly increased. With this structural design, the machine manufacturer constructively reduces the effects of error-inducing variables to a minimum. Because fewer leverage forces apply in comparison to a serial design with a classic guide layout, the manufacturer can increase the rigidity of the FZU/FZP, without having to increase the cross sections of the components. Because less mass needs to be moved, the machine works faster and more dynamic. “Moving less mass also requires less energy. Which results in clear cost benefits”, states Mr. Gänzle, CEO. Additionally, the thermo-symmetrical design makes it possible to omit complex cooling circuits, which also has a positive impact on cost reduction.

By offering the new FZU/FZP42 machine lines, Zimmermann gains a foothold in heavy machining. For a long time, the machine manufacturer only sporadically sold systems in this segment. This has changed following the new developments: “We are already seeing first achievements”, says Mr. Gänzle, CEO, delightedly. “We were able to sell three “heavy” machines in the first quarter alone.” The customers are equally convinced about the technical data and the price-performance ratio. “A particular customer only wanted to purchase one of our machines for post-processing, since they were already using a heavy machining system provided by a competitor. During the discussions they then spontaneously decided on a second machine from Zimmermann”, adds Mr. Hellwig.

Among the new customers is also an automotive manufacturer, which required a new machine for their tool-making, to process large sheet-metal forming tools and to replace older systems. In the end, Zimmermann was able to successfully assert itself against the competition with their FZU42 machine type. The customer realized that the innovative machine concept will enable them to meet their requirements with high machining accuracy and excellent surfaces of their tools. The high tool weights of up to 40 tons do not pose a problem for the FZU42 system, because the components are not being moved. The movement system, consisting of the portal, Z-slide and the milling head, can operate with consistently high dynamics, regardless of the tool weight.

Flexible setup

“We were able to successfully impress with our concept and our price-performance ratio”, says Zimmermann expert Mr. Hellwig. Another important aspect adds to this: The FZU system does not require a solid machine foundation and can therefore be placed flexibly on the factory floor. Extensive constructions, which create high costs and disrupt manufacturing, are completely obviated.

“We continue to develop and are able to find the right answers for many applications”, Mr. Frieder Gänzle, CEO, emphasizes: “We have the right overall package. We offer coherent concepts in all segments. Besides the machines, these include fitting mounts for the spindles, milling heads for the tools and an extensive service.”