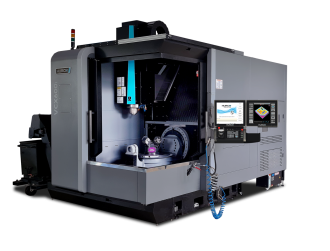

The new Voortman V623 is a high-performance drilling, milling, and sawing machine engineered for continuous, unmanned operation. The V623 can handle a very wide range of profiles, producing them efficiently with a logical output sequence that maximizes cross-transport use. What sets the V623 apart is its innovative gripper truck. This feature virtually eliminates clamping limitations, allowing for the automatic loading of almost any profile without the need for operator intervention or weld-ons.

A standout feature of the V623 is its advanced gripper truck, which eliminates traditional clamping limitations. This innovative mechanism allows for the automatic loading and processing of nearly any profile without requiring operator intervention or weld-ons. The gripper truck is designed to secure material externally, using a hydraulic cylinder to adjust clamping force, which can protect delicate profiles. A sensor system enables the gripper truck to efficiently approach profiles at speeds of up to 60 meters per minute (196.9 ft/min), facilitating a swift and seamless production process.

Integration of VACAM Control Software

The VACAM control software is integral to the V623's operational efficiency. This advanced software provides operators with complete visibility over all buffers on the infeed, outfeed, and short product removal systems. The result is a seamless management process that enhances overall productivity and reduces the need for manual supervision.

Efficient Tool Handling System

The V623's central storage system can hold up to 42 tools, ensuring smooth and efficient tool changes for the machine's three drilling units. This storage system, paired with a pneumatic tool handler, extends unmanned production capabilities by facilitating automatic tool transitions between storage and the drilling spindle’s tool changer.

Versatility and Compact

The V623 accelerates production with three drilling units capable of working on profile flanges and webs simultaneously. It excels in tasks such as drilling, milling, thread tapping, countersinking, and layout marking. The machine uses SK40 units to handle holes and milling operations efficiently. Additionally, a second hydraulically-driven gripper enables the V623 to perform fully automated double miters on both the front and back ends of profiles.

Optimized Space Utilization

To support extended unmanned production, the V623 employs three different outfeed zones to maximize both space and workflow efficiency.

- Automatic Discharge System: Manages clean cuts, offcuts, and short products using a robust conveyor belt to swiftly remove pieces up to 20 mm (0.79 inches) after each cut.

- Short Product Removal System: Features sections with sensors that alert operators when full, ensuring continued smooth operations.

- Pneumatic Drag-Dogs: Equipped with noise-dampening strips, they facilitate the movement of products across diverse zones, ensuring precise positioning and enhancing overall productivity.

The Voortman V623 stands out as a transformative solution in the field of steel processing, incorporating advanced automation and precision engineering to meet the high demands of the manufacturing industry.