OPEN MIND Releases hyperMILL Version 2024

hyperMILL 2024, the latest version of OPEN MIND’s CAD/CAM suite, delivers new turning features and improved algorithms. This makes the digital process chain even more efficient, from CAD data and CAM programming to optimized NC code. Simplified rest machining and interaction with machines are just a few examples of how the software has been further refined.

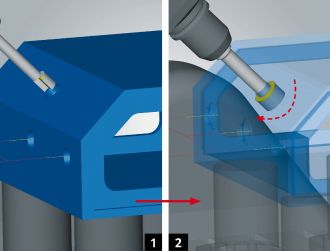

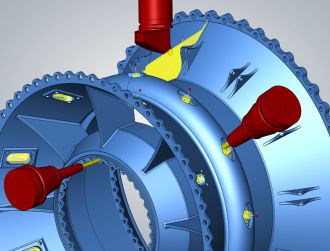

Previous versions of hyperMILL already offer a broad range of functions and strategies for turning, turn-milling and mill-turning. The key extension in hyperMILL TURNING Solutions is turret support for lathes. This also underscores OPEN MIND’s determination to push ahead with the integration of digital twins of machining centers: Lathes with one main spindle, one turret and a Siemens control system are now mapped with all tools true to the original machine with the help of hyperMILL VIRTUAL Machining. Users can conveniently equip the turret with turret holders and tools in the Virtual Machine machining planner and use the resulting setup for NC code simulation.

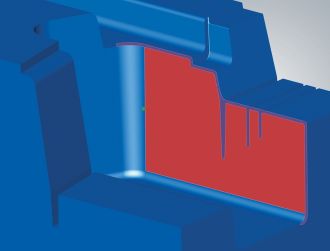

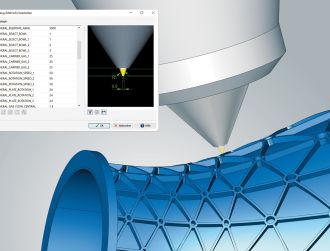

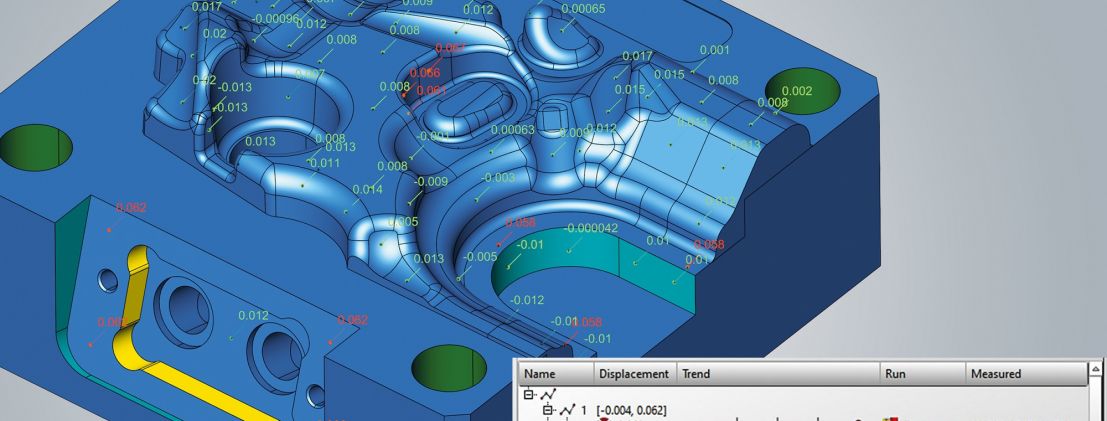

Reading Back Measuring Points

Another useful application of virtual machining technology is the reading back of measuring points. This means that users can use the 3D model of a component to see at a glance which measuring points are outside the tolerance. As a result, it becomes much easier to analyze inaccuracies and tool wear after milling and then compensate for these in the CAD/CAM system. Moreover, the hyperMILL SHOP Viewer makes this new function directly available on the machine tool.

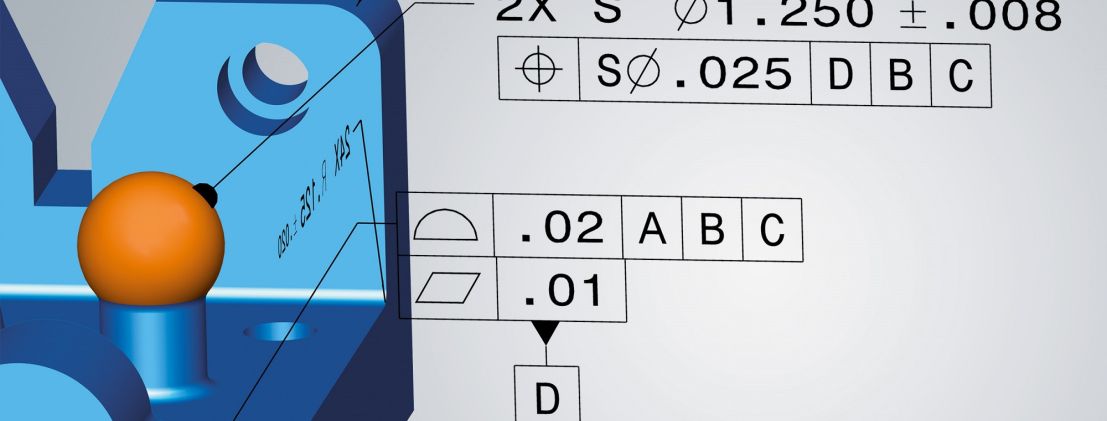

CAD for CAM

hyperMILL 2024 also offers various new features concerning ‘CAD for CAM.’ hyperMILL supports the import of PMI (Product Manufacturing Information) and MBD (Model-Based Definition) data in various formats such as STEP, CATIA V5, SOLIDWORKS, Creo and Siemens. Improved functions for surface modelling now allow users to generate surfaces from a large number of grid curves. Another important CAD innovation is an improved electrode creation strategy that now supports three-dimensional eroding.

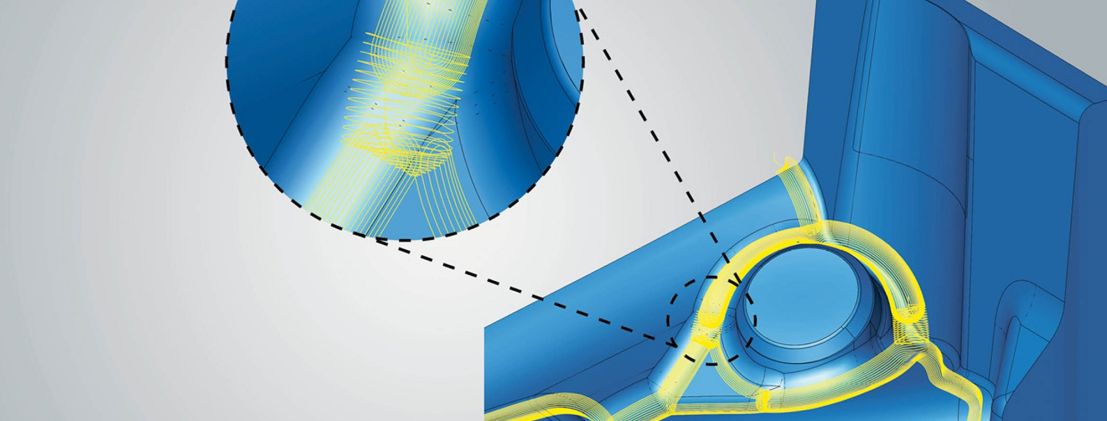

5-Axis Path Correction

Comparable to the 3D radius correction to account for the tool wear or deflections, 5-axis path correction is now possible – initially for Heidenhain control systems. Vectors are written to the cutter contact point in the NC program to ensure precision correction on the machine control. The NC control uses these contact vectors to move the NC points by a defined adjustment value during machining.

Improved Machining Strategies

A new algorithm for rest material detection ensures automatic complete detection of all rest material areas in both 3D and 5-axis machining. The algorithms for calculating the trajectory have also been optimized. The cutting-edge machining for punching tools 3D strategy has undergone several improvements. This includes the optimization of collision avoidance when performing machining based on a reference job. Machining is carried out collision-free as far as this is possible for the given tool clamping length. The ‘Soft overlap’ option makes it possible to smoothen the approach and retraction moves. A new algorithm also improves the toolpath calculation for 3D plane machining, resulting in even faster, more uniform and more tool-friendly machining.

Safety in ‘Unmanned’ Production

To safeguard against long unattended machining cycles, hyperMILL now allows tool breakage monitoring to be activated in the tool database to make it part of the machining program. This information is processed during NC generation on the virtual machine. The generated NC program includes the corresponding control macro call.

Tool Synchronization with the Hummingbird MES

In the new version, tools from the hyperMILL tool database can be synchronized with the Hummingbird MES at the touch of a button. This means that tools used for CAM programming are automatically transferred to the Hummingbird tool management system. All other processes such as machine setup, measuring, tracking and the use of tools in machines are mapped in the Hummingbird MES, thus ensuring a consistent exchange of information within the company.

CAD for CAM Technologies Under a Single Name

OPEN MIND has always been known for its pioneering CAD/CAM solution, which seamlessly combines CAD functionalities with CAM programming. Bringing these two sides closely together results in considerable time savings in workpiece processing and shows that CAM without CAD is no longer viable today. To make this even clearer, hyperMILL will combine CAD and CAM under a single name from Version 2024 onward. Jasmin Huber, Director of Marketing & Communication at OPEN MIND Technologies AG, explains: “With hyperMILL CAD/CAM, we bring together what belongs together. Our innovative and powerful complete CAD/CAM solution combines unique CAD and CAM technologies for high-performance, end-to-end processes in both areas. We are thus consolidating ‘CAD for CAM’ for the future and are further improving our software for users.”