New partnership provides G-Code simulation within Mastercam

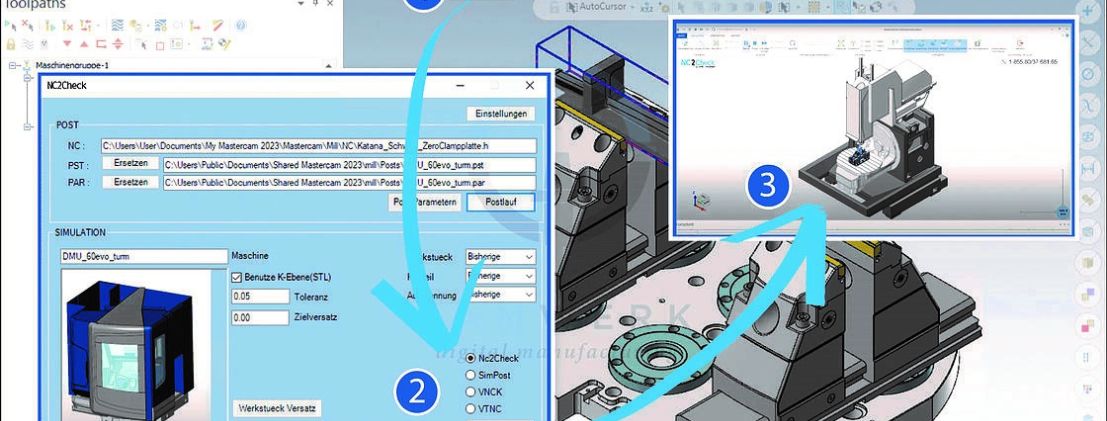

CNC Software, developers of the CAD/CAM software Mastercam, has partnered with CAMWERK to provide customers with a unique and easy to use fully-integrated machine solution called NC2Check. The Mastercam developers worked closely with CAMWERK to build a solution for G-code simulation within Mastercam. The integration gives Mastercam customers a solution for avoiding machine damage, downtimes, failures, and makes their production and programming even more efficient and error-free.

N2Check precisely simulates the CNC machine and the entire process of machining. By verifying the NC code through NC2Check, users have an NC code-based virtual machine simulation of all movements. NC2Check helps users detect errors that lead to machine downtime, damage to the workpiece, or even expensive collisions on CNC machines before the real machining even begins.

“We are excited to partner with CAMWERK on a complete mapping of the entire machine tool and simulation of NC programs based on G-code and make it available to over 300,000 users,” said Stas Mylek, Partnership Program Manager at CNC Software. “The collaborative effort between both companies provides Mastercam users complete machine simulation for detecting issues such as travel limits or potential workpiece collisions before machining takes place,” Mylek continued.

NC2Check is an add-on to Mastercam that installs as a single button on the ribbon bar interface. The single button allows users to launch NC2Check to provide full simulation and G-code verification from within the Mastercam session.

Bircan Öztürk, Director for CAMWERK says, “With NC2Check, you can see collisions and errors directly on your PC and run on your machines completely virtually. We do not offer G-code simulation in the classic definition, we offer our customers the freedom to create ideas and creatively use ideas elsewhere in the company instead of looking for errors in the NC program, and to run in every single part on the CNC machine. It is a small tool, but its effect in production makes it a real-time miracle for everyone.”