Mazak Solid Mazatrol programs in a matter of minutes

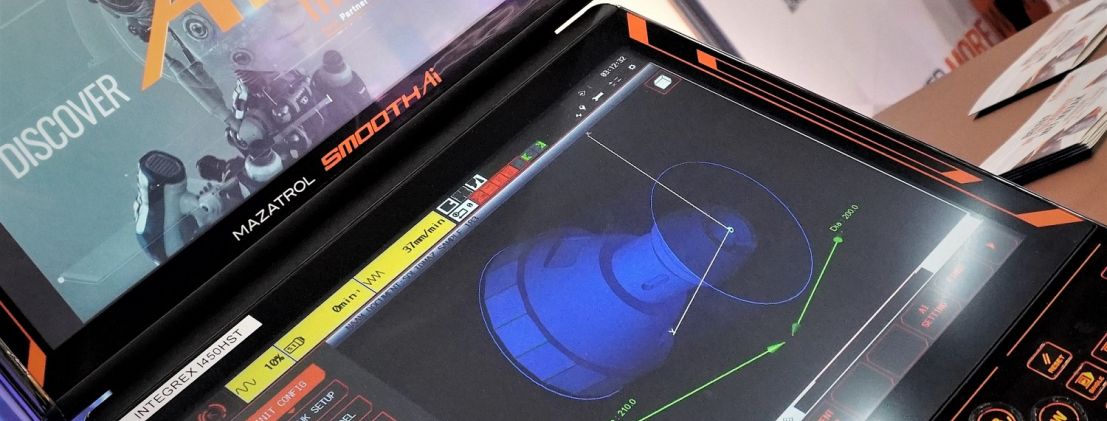

With an eye on automation and process optimisation, many people are quickly seduced by beautiful robotic arms, attractive pallet systems and trendy self-driving vehicles. Less conspicuous alongside all this moving hardware, but certainly just as interesting to consider, are new software solutions. One interesting feature that Mazak has added to the Mazatrol SmoothAi CNC controller is Solid Mazatrol. The solution makes programming easier and faster.

Although developments in the area of machinery are far from coming to a halt, according to Mazak, the biggest innovations today are to be found in software. "Our customers can achieve higher productivity by investing in automation and digitalisation. The productivity gain you realise with a new machine that is just slightly faster than the previous model is negligible. The goal is to have that spindle running 24/7. Only then is a real productivity improvement possible. Manufacturing companies can only achieve this with the help of automation and software solutions." Mazak's SmoothAi is one of those solutions. The CNC technology can use data and artificial intelligence to help the manufacturing sector solve common problems. These include the shortage of people and skills, the increasingly rapid introduction of new products and maintaining product quality, productivity and profitability.

A new functionality in SmoothAi that can solve the skills shortage is Solid Mazatrol. Mazak has developed this feature to simplify and speed up the programming of relatively complex workpieces. With Solid Mazatrol, programmes can be automatically generated from 3D models, using artificial intelligence to intuitively learn and understand the cutting strategies used by the manufacturer. This can reduce programming time by as much as 90%, according to Mazak.

Five steps to a programme

Solid Mazatrol is the advanced sibling of Mazak’s 3D Assist function and is suitable for programming Integrex machines and some CNC turning centres. After loading a STEP file 3D Assist assists users to manually transfer all coordinates into the programme. Solid Mazatrol does this fully automatically. In just five steps, users can programme a product from a Solid or a STEP file. The software guides the user through the various steps in a user-friendly manner. In addition, Solid Mazatrol is self-learning. For instance, if the software itself chooses drilling first and then facemilling, but the programmer prefers milling first and then drilling, the software adopts that strategy for the next time. In this way, programming becomes increasingly efficient.

However the software is really smart, Mazak points out that expert knowledge is always needed with this kind of programming. With a three-metre-long axis, for example, the system does not take into account the method of clamping to prevent vibrations. The programmer will always have to take care of the clamping and positioning of the supporting tools to prevent chatter and vibrations.