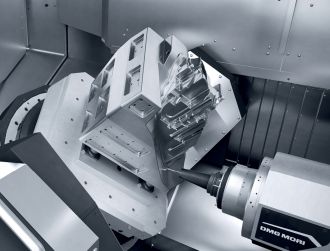

New generation DMU 80 P duoBLOCK from DMG MORI offers top level 5-axis machining

The duoBLOCK concept from DMG MORI has long been established in branches such as the aerospace industry, automobile technology, mechanical engineering or tool and mould construction. The highly stable design of the 5-axis universal machine, its long-term accuracy and the highest precision with up to 5 μm positioning accuracy strengthen the worldwide market leadership when it comes to complex production. With the newly developed fourth-generation DMG MORI has succeeded yet again in improving the core features of its DMU 80 P duoBLOCK – precision, performance, efficiency – by up to an amazing 30 percent compared to the previous generation and in setting new standards.

30 percent higher precision

The proven duoBLOCK from DMG MORI contributes to long-term accuracy and precision as much as the intensive cooling measures of the DMU 80 P duoBLOCK in its fourth generation: The headstock including housing, B-axis motor and motor spindle is part of these cooling measures as well as the C-axis motor in the NC rotary table, the Y- and Z-axis motor and the feed axes and linear guideways in the X-, Y- and Z-directions. A so-called spindle-growth sensor monitors and compensates temperature and speed dependent displacements of the spindle. An optional precision package also encompasses the X-axis motor, the ball-thread drive nut in X-, Y- and Z-direction, the machine bed including Thermoshield as well as the gears in C- and B-axis in the cooling concept. These measures achieve up to 30 percent higher workpiece accuracy, compared to the machines of the 3rd generation.

30 percent more rigidity

This is still based on the highly stable duoBLOCK. An optimized component structure and strengthened components – size 55 linear guideways in the Y-axis, ball-thread drives with 50 mm diameter and larger bearings in the B and C-axis have increased the overall rigidity of the duoBLOCK by 30 percent. The high level of overall rigidity of the 4th generation DMU 80 P provides the basis for heavy machining with the new powerMASTER 1000 motor spindle in the B-axis. Its maximum torque of 1,000 Nm constitutes an increase of 130 percent. It has an output of 77 kW and a maximum speed of 9,000 rpm. Compared with the competition, DMG MORI achieves 75 percent higher chip removal volume here.

30 percent lower energy consumption

The list of impressive properties of the DMU 80 P duoBLOCK is rounded off with intelligent needs-based power units in the area of cooling, cooling lubricant system and hydraulics. When combined with the controlled chip conveyor and the optionally available frequency-controlled pumps, the energy consumption of this 4th generation DMU 80 P duoBLOCK is reduced by up to 30 percent.

New B-axis and wheel magazine

The topic of innovation is addressed by DMG MORI with a revised B-axis and a fast, compact tool magazine. The new patented B-axis with the highest rigidities and the newly integrated cable track ensure higher quality with a longer service life of the cables and an improved interference contour of the B-axis. In addition, the already high level of rigidity of the B-axis concept with a 45° swivel plane has been improved yet again by 20 percent thanks to the use of larger bearings.

The new and compact wheel magazine also ensures maximum flexibility and productivity with up to 363 tools, the shortest tool changeover times of 0.5 seconds and the possibility of parallel primary time tooling. The wheel magazine is the most compact on the market – despite its 123 tool pockets the machine has a 41 percent smaller footprint.

CELOS and the new DMG MORI design

The new DMU 80 P duoBLOCK is available with CELOS from DMG MORI and 21.5” ERGOline and SIEMENS. In addition, this machine can be delivered with Operate 4.5 on SIEMENS 840D solutionline. CELOS from DMG MORI simplifies and accelerates the process from the idea to the finished product. CELOS APPs enable continuous and digitalized management, documentation and visualization of job, process and machine data. In addition, CELOS is also compatible with PPS and ERP systems, it can be networked with CAD / CAM applications and is ready for trendsetting CELOS APP expansions. The DMU 80 P duoBLOCK is now also available in the new joint DMG MORI design that was introduced in 2014. This reflects the holistic high-quality standard of the innovative leader and Impresses with more functionality and increased user-friendliness. The large viewing windows, for example, enable optimum monitoring of the manufacturing process. The accessibility of the work area and chip flow during machining are also indications of this high degree of user comfort. Another outstanding feature of the new DMG MORI design worthy of note is the premium machine housing with its special fine structured coating. These long-life surfaces feature higher scratch resistance and better overall protection against damage thus further boosting the high-value retention of the high-tech machines. In addition to all these technical features, customers can choose between two machine designs. The new DMG MORI design is available in either “BLACK” or “WHITE” at no extra cost.