DMG MORI INH 63 and INH 80 set New Standards in Horizontal Machining

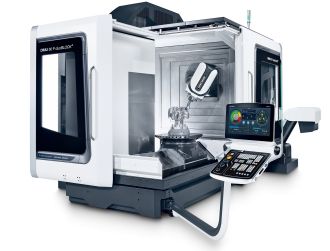

The new INH 63 and INH 80 horizontal machining centers from DMG MORI set new standards in horizontal machining. In combination with Machining Transformation (MX) from DMG MORI, the two models support users on their way to a sustainable, efficient and competitive future of CNC manufacturing. The horizontal machining centers are designed for demanding components in tool and mold making as well as in the energy and greentech sector – including, for example, drive technology for electromobility. The focus is also on complex parts for the aerospace sector. The INH 63 can handle 630 mm pallets, while the INH 80 is designed for 800 mm pallets. With their stability, precision and machining versatility – they are available in a 5-axis version – the two machines act as the perfect foundation at all levels of the machining transformation. They allow a high degree of process integration, can be flexibly automated and are optimally prepared for the digital transformation.

A symmetrical, FEM-optimized structure, twin ball screws in the X, Y and Z axes and the offset X-slide in the frame column give the INH 63 and INH 80 their high stability and allow dynamic machining. The necessary precision is guaranteed by twin measuring systems from MAGNESCALE and the reliable cooling of the ball screws and other heat sources. These minimize thermal displacements and changes in the machine structure. Both horizontal machining centers are also characterized by their wide axis ranges, which ensures efficient chip removal. The INH 63 and INH 80 are impressive from light machining to the high-load range. As standard, they have a powerMASTER spindle with a speed of 12,000 rpm and a torque of 808 Nm. Spindles with up to 16,000 rpm or 1,414 Nm torque (8,000 rpm) are optional. In all three cases, a long warranty of 36 months applies with no limit on running time.

Ergonomics and machining versatility

In the 5-axis version of the new INH machining centers, the swivel rotary table has large bearings and two high-performance torque motors as the A-axis. This eliminates backlash and ensures maximum precision. The ergonomically accessible work area is so large that it offers sufficient space even for overhanging tools. With the ability to machine negative angles, the INH 63 and INH 80 meet an essential requirement in die and mold making. The table can also be fully swiveled through 180°. This enables “upside-down” machining and creates immense advantages, particularly for the use of milling-turning technology.

Holistic innovations for the Machining Transformation (MX)

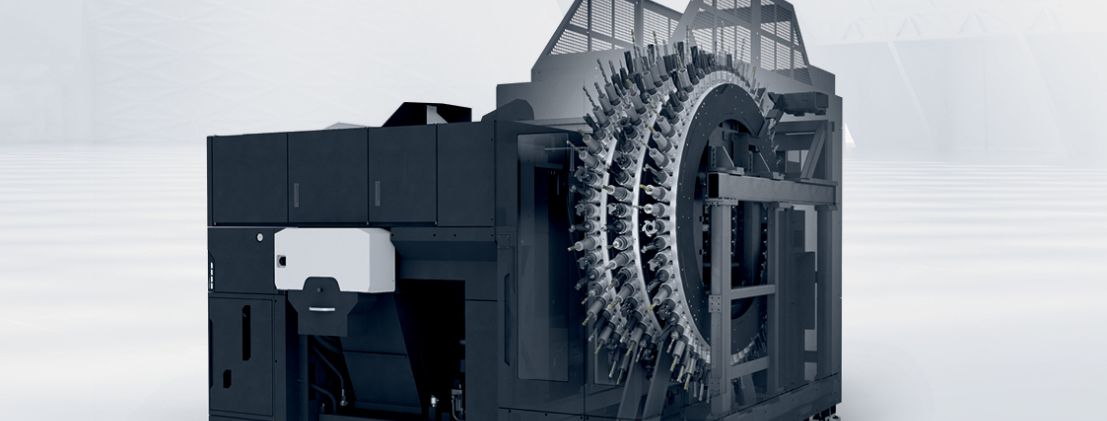

The INH 63 and INH 80 are good examples of the strong focus that DMG MORI places on sustainable progress in the form of Machining Transformation (MX). Process integration, automation, Digital Transformation (DX) and Green Transformation (GX) are the main pillars here. Their increasing interaction clearly shows that sustainability and operational excellence are by no means contradictory goals but can successfully go hand in hand. The integration of different manufacturing processes in one machine – turning, milling and other processes such as measuring or gear cutting – shortens the process chain. Set-up times are reduced, while quality increases. Overall, resource efficiency increases, which contributes to sustainability. Integrated into flexible production cells and systems, the INH 63 and INH 80 can also work unattended for up to three shifts. Automated tool and pallet handling and the intelligent

CELL CONTROLER LPS 4 master computer increases the productive spindle hours from 2,000 to over 6,000 per year compared to the stand-alone installation. The equipment with digital technologies also allows integration into holistic production systems. The GREENMODE also has a direct impact on the Green Transformation (GX). It reduces the energy consumption of the machines by over 30% and optimizes the use of resources at the same time.

Integrated manufacturing processes

Using the example of a high-precision spiral bevel gear for industrial wind turbines, the INH series demonstrates its capabilities in terms of efficiency and sustainability. The gear element is made of robust steel and measures ø 482 x 66 mm. By integrating manufacturing processes such as 5-axis milling, gear cutting and in-process measuring in one work area, both horizontal machining centers can completely manufacture the bevel gearbox in a single clamping operation. Transport between the previously separate machining stations is no longer necessary. This saves idle time and increases precision at the same time. This is because each repositioning creates space for potential errors. Gear cutting with standard tools plays a major role in complete machining. The 5-axis performance combined with the respective DMG MORI technology cycles enables gear-cutting processes such as roughing and finishing on standard machines. Specialized and therefore expensive single-purpose gear-cutting systems are not required. With regard to digital transformation (DX),

1:1 simulation and the accompanying analysis of process data ensure optimum machine utilization. This reduces the risk of machine downtime and ensures greater energy efficiency. Up to 80% of power consumption can be saved per component. All in all, this use case shows that the INH series combines all elements of Machining Transformation and can be used to optimize machine utilization. All in all, this application shows that the INH series combines all elements of the Machining Transformation and applies them to future markets such as wind power. The INH 63 and INH 80 combine economic efficiency with ecological foresight, creating a role model for the machine tool construction of the future.

-

The efficient precision machining of a high-precision bevel gear in a single clamping operation on a standard machine such as the INH is a prime example of the combination of mechatronic excellence and Machining Transformation (MX). -

The machines of the INH series can be upgraded to flexible production cells and systems with various system offerings for automated tool and pallet handling.