Discover world premieres and innovations at DMG MORI's Open House 2024

From 22nd January to 2nd February 2024, Pfronten will be dedicated to the latest technologies for future-oriented production for the 29th time. For the Open House, DMG MORI will transform its largest European production site into a 4,200 m² showroom, demonstrating pioneering solutions in the field of machine tool construction. With more than 45 high-tech machines, over 15 automation solutions and technological expertise in the leading sectors of semiconductor, aerospace and medical, “The Home of Innovation” will present the latest and most modern developments for sustainable process optimization. Highlights of the exhibition include the world premiere of DMF 400|11 as a perfect example of process integration and the PH Cell 500 as an innovation in the field of modular pallet handling. Another highlight is CELOS X. The holistic digital and data-based ecosystem creates additional potential in the optimization of manufacturing processes. The Lasertec Showroom completes the technological range of services with efficient products for additive manufacturing, while the Academy Area offers insights into DMG MORI's extensive training and further education program.

“The Home of Innovation is based on the four pillars of Process Integration, Automation, Digital Transformation (DX) and Green Transformation (GX)," says Irene Bader, Member of the Board of DMG MORI COMPANY LIMITED, looking ahead to the upcoming Open House in Pfronten. “These pillars form the foundation for Machining Transformation (MX), with which we support our customers on their way to future-oriented production.” The overarching goal is to make manufacturing processes more efficient and sustainable, to ensure customers remain globally competitive and successful in the long term.

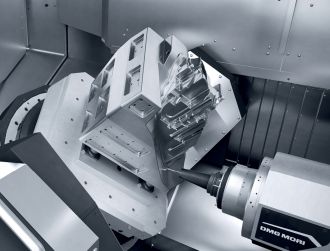

World premiere: DMF 400|11

The DMF 200|8, DMF 300|8 and DMF 300|11, which have been developed from the ground up, are further examples of DMG MORI's innovative competence, which has been demonstrated repeatedly in recent years. Based on this pioneering moving column concept, the machine tool manufacturer is now also presenting the largest model in the series, the DMF 400|11. Compared to the predecessor model DMF 360|11, the world premiere impresses with an X-axis travel increased by 400 mm and 150 mm more in the Z-axis. The solid construction results from the cast-iron machine bed, three linear guideways in the X-axis and ground and cooled ball screws. This makes the moving column machine the perfect companion for machining demanding large components – from structural parts and long beams to components for tool and mold making. With travels of 4,000 x 1,100 x 1,050 mm, the DMF 400|11 offers many possibilities for universal machining. The optional partition wall, which can be quickly integrated, divides the machining area into two separate work areas, allowing components to be set up during machining. The modular system is complemented by an FD rotary table for demanding mill & turn operations, making the DMF 400|11 perfect for process integration and driving forward Machining Transformation (MX).

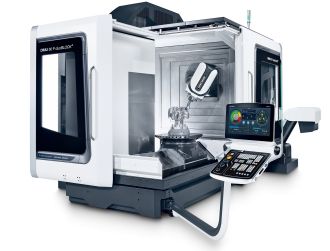

Innovation: PH Cell 500 Modular pallet handling

DMG MORI will be demonstrating the possibilities of Machining Transformation by means of Automation at the in-house exhibition with the PH Cell 500. This innovation extends the series of modular pallet handling systems with a compact model for transfer weights of up to 500 kg. It is compatible with the DMU 65, the DMU 75 monoBLOCK 2nd Generation and the DMU 65 H monoBLOCK. Depending on the configuration of the rack modules, the PH Cell 500 offers space for up to 32 pallets. The maximum workpiece dimensions are 500 x 500 x 750 mm. The transfer weight is up to 500 kg. Like the other models in the series, the PH Cell 500 is ergonomic and easy to operate thanks to the Pallet Master software. With the consistent further development of its pallet handling systems, DMG MORI is underlining the importance of automation as a fixed pillar in Machining Transformation (MX). The new pallet automation enables highly flexible, automated production of small batch sizes and individual parts. The reason for this is the modularity of the system, which enables customized configuration.

Innovation: CELOS X

Around ten years after introducing the world's first app-based machine control, DMG MORI is revolutionizing manufacturing technology once again with

CELOS X. The aim is to put Machining Transformation (MX) into effect and to pave the way to Digital Transformation (DX) for manufacturing companies and service providers. Being the most advanced DX technology CELOS X enables users to shape their manufacturing future in a self-determined and secure way. The CELOS X ecosystem offers a holistic solution for Digital Transformation of manufacturing and their vertical integration in a company. It comprises both the CELOS Xperience and the CELOS Xchange platform. The interaction of these two elements enables a comprehensive and seamless digital experience for users. With its high functional diversity, CELOS X offers unique consistency across all DMG MORI control variants. Regardless of the native NC control of the machine tool, the content of CELOS X is available on all offered controls to almost the same extent.

CELOS Xchange acts as the multifunctional control center of the application and data management of CELOS Xperience within the CELOS X ecosystem. As a cloud-based data room, CELOS Xchange also enables the bidirectional integration of the manufacturing workshop into the company's IT and, in the future, the open and secure exchange of data with partners along supply chains and within global value creation networks. CELOS Xperience is the digital toolbox for all CELOS Apps and software systems within the CELOS X ecosystem. The available solutions demonstrate the holistic customer-added value of CELOS X. This opens up a wide range of possibilities, as all applications and workflows aim to simplify machine operation, increase the number of spindle hours and optimize energy efficiency simultaneously.

A targeted look into the future of manufacturing

The innovative manufacturing solutions at the in-house exhibition in Pfronten and the wide-ranging supporting program will give trade visitors a holistic view of the future of manufacturing. Irene Bader is looking forward to the two-week event at the start of the year: “CELOS X is an important building block, with which we will strengthen the pillar of Digital Transformation (DX) additionally. In this way, we are making a significant contribution to the competitiveness of our customers, and we are driving sustainable production further forward.”