High-speed cutting with speedMASTER 30k from DMG MORI

DMG MORI components make a significant contribution to quality and reliability in machining. Many years of experience and technical know-how flow into the products developed and manufactured by DMG MORI – as in the case of the speedMASTER 30k. The new high-speed spindle achieves a speed of up to 30,000 min-1.

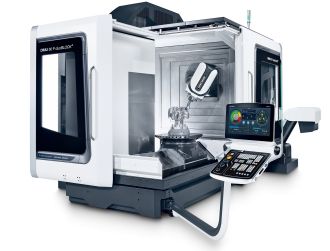

speedMASTER spindles are designed for high-speed milling applications and are used in horizontal and vertical machining centers such as the NHX 4000/5000 3rd Generation and NVX 5000 2nd Generation as well as the monoBLOCK series. The previously available spindle range already reached speeds of up to 15,000 min-1 or 20,000 min-1. With the new speedMASTER 30k, DMG MORI enables even faster milling and shorter machining times.

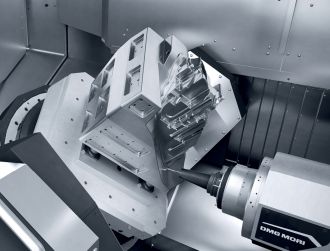

Great for small, complex workpieces

The speedMASTER 30k is an optimal spindle for users who want to implement high-speed milling over long machining sequences on tool and mold parts. In addition, the high-speed spindle shows its strengths when tools with small diameters are used. This allows small, complex workpieces to be machined highly efficiently and with optimum quality – for example, when drilling semiconductor components. Existing machines can be easily upgraded to the speedMASTER 30k, as it has the same mounting interface as the 15,000 min-1 and 20,000 min-1 spindles.

The development of the speedMASTER 30k is the result of many years of experience in high-speed milling. Their manufacture is carried out entirely at DMG MORI, so that the machine tool manufacturer can ensure the highest quality. As with all MASTER spindles, a warranty of 36 months with no term limit applies. Furthermore, the speedMASTER 30k is an additional step into a more environmentally friendly production. The significantly shorter machining times reduce CO2 emissions and power consumption.