GROB marks a century of progress at 2026 in-house exhibition

The 2026 GROB in-house exhibition in Mindelheim will highlight one hundred years of technological development with a program that combines historical context and modern production innovations. From March 17 to 20, visitors will see new machine concepts, expanded automation solutions, and digital manufacturing tools, supported by a broad technical program and extensive insight into GROB’s production facilities.

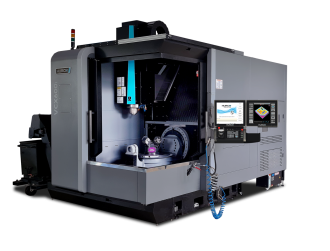

The event presents more than forty machines in operation, ranging from universal machining centers to systems for machining technology, electromobility, and additive manufacturing. Four dedicated areas focus on semiconductor applications, aerospace and defense, energy technology, and die and mold. Over seventy guided tours through fourteen production halls provide a detailed view of the company’s vertical integration and process capabilities. More than sixty exhibitors in tool technology, clamping devices, CAD/CAM, and digital simulation complement GROB’s program. Additional expert areas such as GROB Service, customer training at the GROB Technical Academy, and the new center for quality-checked used machines broaden the scope. A historical exhibition titled #100GROB illustrates the company’s path from a small machine tool builder to a global system provider, supported by original machines and archival documentation.

New systems for evolving production needs

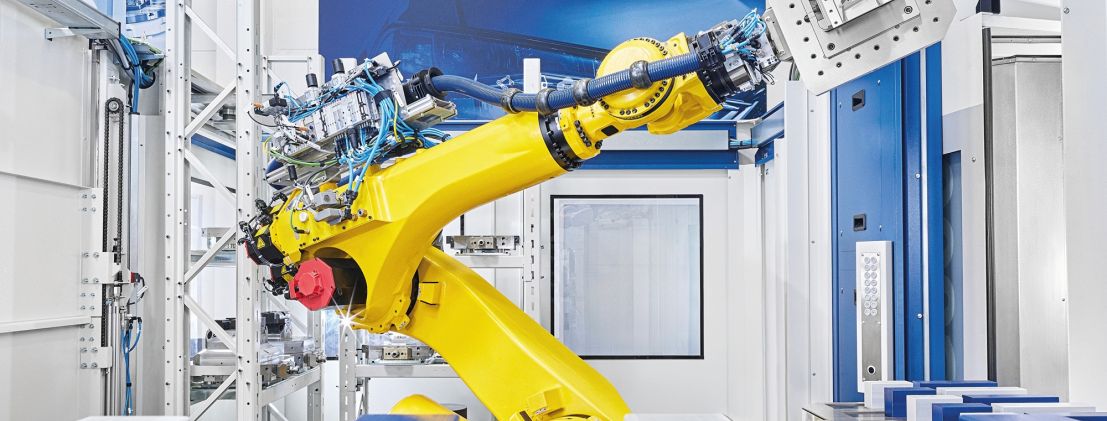

The exhibition introduces three premieres that target key manufacturing challenges. The GP1350 5-axis portal milling machining center expands capabilities for large workpieces. Its rigidity and spacious working area address requirements in die and mold, energy technology, and aviation. The GRC-M60 robot cell extends GROB’s modular automation platform and is designed for flexible integration into existing manufacturing environments. In addition, the GROB COSERA MES/MOM system provides digital control and documentation of part flow on the shop floor, increasing transparency, efficiency, and process reliability. According to CSO Christian Müller, the exhibition connects GROB’s technical heritage with future production demands by presenting solutions aimed at higher efficiency, improved process reliability, and complete traceability.

A strategic view of future production

With the combination of historical context, technological depth, and structured interaction with visitors, the 2026 exhibition underscores GROB’s position in a rapidly evolving manufacturing landscape. The company highlights that production technology can be sustainable, efficient, and highly accurate. The event provides a platform to evaluate current innovations and examine their potential for future production environments. Visitors gain direct insight into developments that influence machining, automation, and digitalization. The exhibition offers access to specialist discussions, live demonstrations, and a broad overview of technical advancements as GROB marks its centennial. Tickets are available at the event website.

GROB in-house exhibition 2026 at a glance

• March 17–20, 2026, Mindelheim

• Historical exhibition area #100GROB

• Over 40 machines from universal machining to e-mobility and additive manufacturing

• Special areas for semiconductor, aerospace and defense, energy technology, and die and mold

• Premieres: GP1350, GRC-M60, GROB COSERA

• More than 70 tours in 14 production halls

• Over 60 exhibitors