BIG KAISER collet improves cutting tool security

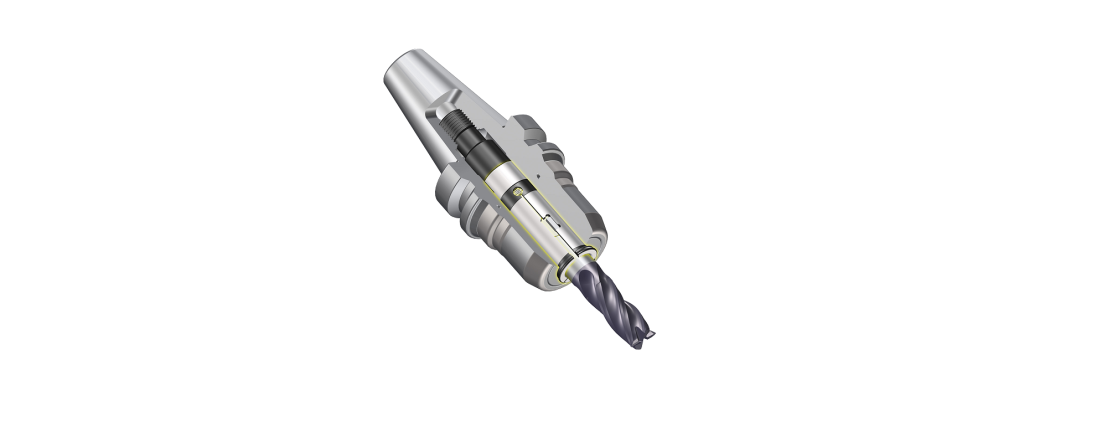

BIG KAISER announces the PG (perfect grip) Straight Collet. The collet includes a new anti-pullout system which locks the collet and cutter to the toolholder body, to eliminate cutter slippage or pulling out during demanding metal removal applications. It is particularly suited to high dynamic milling and high-speed milling in difficult materials.

Unlike other systems, the new PG Straight Collet from BIG KAISER does not require the purchase of expensive specially modified endmills, Instead, it uses existing standard carbide or HSS endmill designs. Standard notches found on Weldon-type endmills readily accept the locking key insert of the PG system, thus enabling fast and easy assembling. “By improving cutting tool security, the PG collet gives manufacturers greater confidence when machining expensive materials and very large or complex parts, especially those within the aerospace industry where part costs can be extremely high.,” said Giampaolo Roccatello, Chief Sales & Marketing Officer for Europe at BIG KAISER. “When machining happens at the end of the process, a failure or tool slippage would ruin the whole part, incurring a big financial penalty.”

The PG collet is for use with BIG KAISER’s MEGA Double Power Chuck and Hi-Power Milling Chuck. To improve compatibility, one holder fits four sizes, due to the reduction sleeve used in the collet. Even if a tool is damaged and cannot be removed from the collet, the collet itself can be disassembled from the holder. Three sizes of collet with the anti-pullout system are now available: 10 mm, 12 mm and 16 mm. While larger sizes have been previously available, this is the first time that customers can mill in difficult materials (such as Inconel and titanium) down to only 10 mm in diameter.

At EMO 2023 (Booth F20 in Hall 3), BIG KAISER will be showing its full range of high-precision systems, including the new PG collet. EMO 2023 takes place in Hannover, Germany, from September 18th to 23rd, 2023.