BIG KAISER provides full automatic fine boring with EWA 68

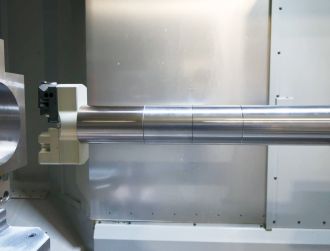

BIG KAISER, a global leader in premium high-precision tooling systems and solutions for the metalworking industries, announces the new EWA 68, an intelligent fully automatic fine boring tool which performs closed-loop boring operations without a human operator.

With the EWA 68, there is no need to stop the machine tool to take measurements and manually adjust the boring tool, which therefore saves time, increases productivity and reduces failure rates due to human error. This reduces costs and improves accuracy, enables handling of multiple bore sizes and repeatable bores, and avoids time-consuming manual wear-out compensation.

The EWA 68 is available with three different insert holders, supporting a wide range of diameters from 68mm to 134mm. It delivers adjusting precision of ±2µm. “The EWA 68 is the latest version of our EWA system, which provides automation at a level far above any competitive product – saving time and money for our customers,” said Giampaolo Roccatello, Chief Sales & Marketing Officer for Europe at BIG KAISER. Developed solely by BIG KAISER, the EWA system is based on BIG KAISER‘s EWE digital fine boring heads and the EWN precision boring heads.

At EMO 2023 (booth F20 in Hall 3), BIG KAISER will be showing its full range of high-precision systems, including the new EWA 68 working in operation on a FANUC CNC machine. EMO 2023 takes place in Hannover, Germany, from September 18th to 23rd, 2023.