DMG MORI, Machining

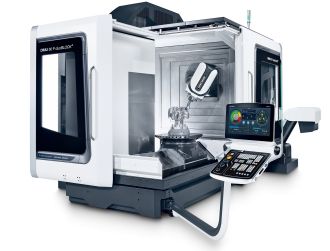

DMG Mori Unveils Next-Generation DMU 60 eVo 2 for Advanced 5-Axis Machining

The newly introduced DMU 60 eVo 2nd Generation represents a significant evolution in 5-axis universal machining, designed to address growing demands for precision, flexibility, and productivity. Built on its proven machine concept, the DMU 60 eVo 2 features unique table kinematics and integrates multiple manufacturing processes, including mill-turn machining, gear hobbing with gearSKIVING technology, and grinding. This multifunctional machining center adapts to the diverse needs of industries while maximizing efficiency.

With advanced automation options enabling around-the-clock operation and modern digital control systems such as SINUMERIK ONE and HEIDENHAIN TNC 7, the machine also aligns with the ongoing digital transformation in manufacturing. The DMU 60 eVo 2nd Generation reflects a forward-looking approach to machining technology and production optimization.

Maximum flexibility, precision at the highest level

The DMU 60 eVo 2. Generation can be used flexibly in numerous industries and meets the highest requirements for accuracy in the micrometer range (4 µm in the circular form test). Whether for the smallest tolerances or fast, highly productive machining - the reliability and precision of the machine meet every industrial requirement and are unique in its segment. With an extended work area and a table load limit increased by 100 kg (up to 500 kg), the DMU 60 eVo 2. Generation makes a major contribution to future-proof production in a wide range of applications.

Robust construction and cooling technology for constant precision

A stable and temperature-controlled machine bed made of hybrid mineral casting and the gantry design give the new DMU eVo generation its exceptional rigidity as the basis for high-precision machining. The thermo-symmetrical design and a comprehensive cooling concept keep critical components at a constant temperature, including the guide carriages, the Y-slide, the headstock and the B-axis. This guarantees maximum positioning accuracy and thermal stability. The DMU 60 eVo 2. Generation is also available as a µPrecision version, enabling it to machine even the most demanding precision components with high accuracy. The complete enclosure of the work area prevents coolant contact and increases the service life of the machine, while direct-drive ball screw drives and linear motors ensure high dynamics and also contribute to precision.

Powerful spindle portfolio

The DMU 60 eVo 2. Generation spindle portfolio joins the ranks of efficiency and precision-enhancing features. It offers speeds of up to 40,000 min-¹ and includes speedMASTER models in various performance classes. High-speed spindles with a cooled shank produce the best surfaces - also with the highest precision, so that the universal machining center can also competitively meet applications in the most demanding industries.

Productive thanks to flexible automation solutions and large tool magazine

The competitiveness of the DMU 60 eVo 2. Generation is also increased by its compatibility with all DMG MORI automation solutions, such as the WH Cell workpiece handling system, Robo2Go Milling or PH Cell pallet handling. The space-saving machine layout (the footprint has been reduced by 20%) allows optimum integration into production. The large tool magazine with up to 300 pockets makes the DMU 60 eVo 2. Generation an ideal solution for highly dynamic and precise 5-axis simultaneous machining in automated production. Thanks to an innovative tool shutter, the chip-to-chip time has been reduced by one second to just 4.5 seconds, which further increases the machine's efficiency.

Large workspace, perfect ergonomics and ease of use

The DMU 60 eVo 2. Generation is easily accessible for both manual operation and crane loading thanks to the ergonomic, straight work area door. Compared to its predecessor, the work area is 40% larger at 750 x 550 x 550 mm, which allows a wide range of components to be processed. A large swivel range and optimum chip removal with steep inclines and a 20% wider conveyor ensure reliable production with perfect chip fall. In addition, all maintenance-relevant components are user-friendly and accessible without a ladder.