DMG Mori showcases next step toward integrated and scalable manufacturing at Open House 2026

During its Open House in Pfronten, DMG Mori will spotlight a wide spectrum of innovations. From 2 to 6 February 2026, the company will demonstrate how five-axis technology, integrated processes, and scalable automation are shaping the future of manufacturing. Visitors will gain insight into applications for the aerospace industry, the semiconductor sector, and mould and die manufacturing.

In an exhibition space covering 4,500 m², more than forty machines and over twenty automation solutions will be on display, including three world premieres. In addition, DMG Mori will open a new 4,500 m² training centre dedicated to developing technical talent. Technology seminars on Machining Transformation (MX) will complement the programme and provide visitors with insights into integrated manufacturing solutions.

Complete production chain

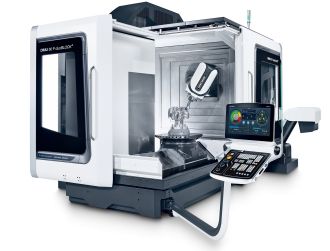

The machine portfolio on display reflects the diversity of machining processes supported by DMG Mori. The world premieres include the CTX 450 4A for universal turning, the second generation of the five-axis horizontal machining centre DMU 65 H monoBLOCK, and the Lasertec 65 DED hybrid for additive manufacturing. With the third generation of Robo2Go, the company is also introducing a new automation solution that is easy to integrate and suitable for various production environments. Small and medium-sized enterprises in particular benefit from the modular and scalable automation offering. Automation modules such as the new Robo2Go and the PH Cell solutions are easy to integrate or retrofit. Support extends across the entire lifecycle of the machine.

In several dedicated zones, DMG Mori will demonstrate how its full spectrum of technologies can be deployed for modern manufacturing. Visitors will see five-axis solutions, powerful turn-mill machines for six-sided complete machining, and a range of advanced processes. A dedicated automation area will showcase the use of autonomous mobile robots. With automatic handling of machine and material pallets, chip trolleys, and tools, AMR models will demonstrate how shopfloors can evolve into automated logistics environments where human intervention is no longer required.

Machining Transformation

With Machining Transformation (MX), DMG Mori outlines a future vision centred on process integration, automation, and digitalisation. By combining machining steps in a single setup and integrating digital support, setup and cycle times are reduced while accuracy increases. The technological foundation is formed by turn-mill centres and horizontal machining centres that can carry out multiple operations in a single process.

MX also focuses on the complete digital chain, including work preparation, NC programming, and quality control. This enables more efficient process organisation and better utilisation of resources. The approach contributes to the Green Transformation (GX), where sustainability is both an ecological and economic factor. This integrated strategy is designed to help companies build future-proof production systems that meet rising demands for efficiency and responsible manufacturing.

Investing in the next generation of skilled workers

DMG Mori places a strong emphasis on knowledge transfer and training to safeguard future innovation. The company has long supported young talent through the DMG Mori Academy, in collaboration with training centres and educational institutions. With the opening of the new training centre in Pfronten, the company significantly expands its in-house training capacity.

The 4,500 m² facility is designed as a modern learning environment that accommodates around 150 students. It is equipped with the latest technologies and practice-oriented training setups. In doing so, DMG Mori aims not only to teach technical skills but also to inspire enthusiasm for mechanical engineering. The next generation of technicians must bring the digital skills, ideas, and innovative approaches needed to support future industrial developments.