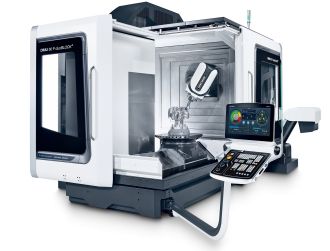

Building on the sturdy foundation of the 3-axis DMV vertical milling machines, DMG Mori introduced the DMX 60 U and DMX 80 U, designed for 5-sided machining of complex workpieces weighing up to 300 and 350 kg, respectively. With workpiece travels of 600 x 600 x 510 mm for the DMX 60 U and 800 x 600 x 510 mm for the DMX 80 U, these universal machining centers address the demands of industries such as general mechanical engineering, die and mold production, and other high-precision applications.

Engineered with a monolithic cast-machine bed and wide roller guides, the DMX U models achieved 45% greater rigidity compared to their predecessors, enabling dynamic machining with rapid traverse rates up to 42 m/min. Comprehensive temperature compensation ensured high thermal stability for consistent precision, while direct position measuring systems and drives in the X and Y axes provided exceptional positioning accuracy, with a concentricity of 6 µm. These new models also aligned with evolving production needs, incorporating automation capabilities, the CELOS X control system, and energy-efficient operations.

Maximum performance with a wide range of spindles

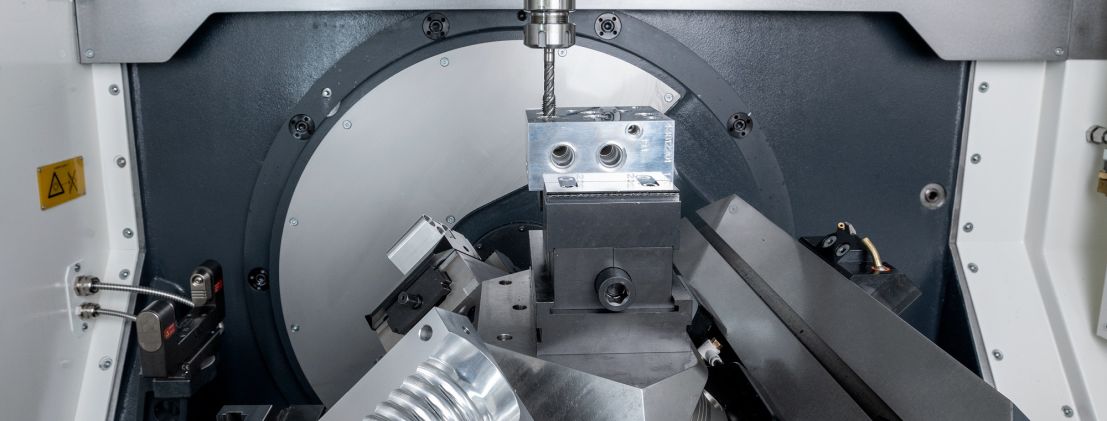

To ensure that the DMX 60 U and DMX 80 U can play to their strengths in as many areas of application as possible, a comprehensive range of spindles is available, starting with the inlineMASTER spindle with 12,000 rpm as standard. SpeedMASTER spindles with a high torque of up to 200 Nm or a speed of 20,000 rpm are also available as an option. As with all MASTER spindles, a 36-month warranty without a runtime limit also applies here. The standard BIG PLUS interface provides additional stability and accuracy during machining.

Machine development with a view to Machining Transformation (MX)

DMG MORI has developed the new DMX U models with Machining Transformation (MX) in mind, taking into account the pillars of process integration, automation, Digital Transformation (DX) and Green Transformation (GX). For example, users can integrate grinding in the work area of the machines so that no additional machines are required or capacities on other machines are spared. Automation solutions such as Robo2Go Milling and MATRIS light as well as the PH 150, PH Cell 300 and PH Cell Twin pallet handling systems enable flexible, automated operation, even in unmanned shifts. At the same time, CELOX X on a SINUMERIK ONE or a HEIDENHAIN TNC7 creates the perfect platform for digital processes. DMG MORI has equipped the two universal machines with GREENMODE with the objective of making production as climate-friendly and economical as possible. Energy-efficient components and intelligent control systems reduce energy consumption here by 10%.