DMG MORI Advances 6-Sided Complete Machining With The New CTX 750 1250

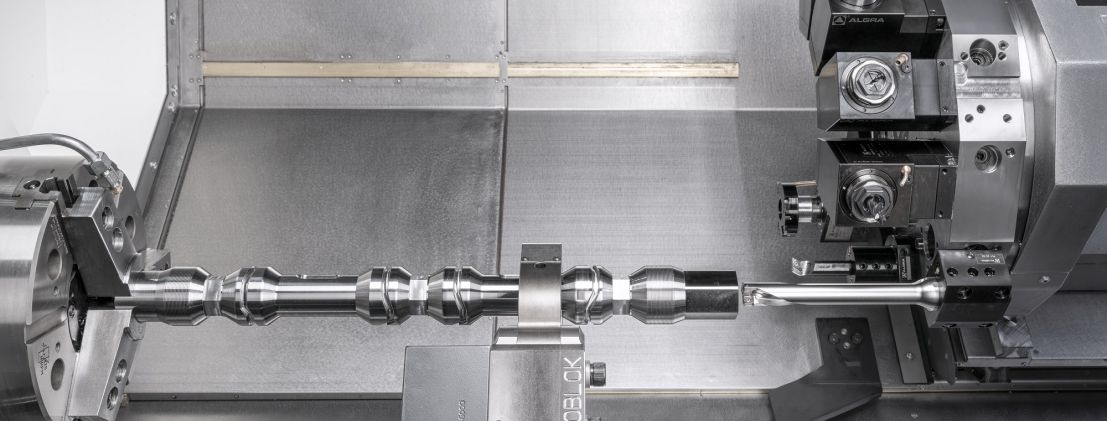

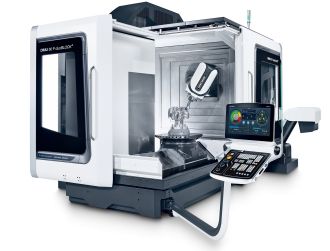

The sixth generation of DMG MORI's CTX universal turning machines introduced the CTX 750|1250, showcasing advancements in precision, performance, and efficiency. Compactly designed on a footprint of 11.7 m², it accommodates workpieces up to ø 700 x 1,290 mm. With dual spindles, an optional Y-axis offering +/- 85 mm travel, and driven tools operating at speeds up to 6,000 rpm, the machine delivers productive 6-sided complete machining. Featuring rigid construction, wide linear guides, advanced cooling, and direct measuring systems, it achieves positioning accuracies of 6 µm, pushing technological boundaries for complex geometries in demanding applications.

The spindles of the CTX 750|1250 play a major role in high-performance machining. The left-hand ISM 127 spindle with 2,500 rpm and up to 1,975 Nm torque is contrasted by an ISM 80 spindle. It achieves 4,000 rpm and 360 Nm. The spindle bore is Ø 127 mm, for bar Ø 125 mm. An ISM 102 spindle for 6-side heavy-duty machining with a torque of up to 770 Nm is optionally available on the right-hand side. The VDI-50 turret with twelve tool positions, used as standard, enables the milling operations required for 6-sided complete machining. The driven tools reach 4,000 rpm and 48 Nm. Alternatively, a high-speed turret with 66 Nm and a direct-drive turret with 86 Nm are available for speeds up to 6,000 rpm.

Energy-efficient and resource-saving universal turning

Sustainable production requires the use of both economical and sustainable solutions, with which DMG MORI is driving forward the Green Transformation (GX). In the case of the CTX 750|1250, for example, low-friction guides and a low-consumption lubrication system are used. The machine has inverter technology for the hydraulic unit and frequency-controlled coolant pumps. The universal lathe also works with advanced synchronous motor technology, motor brakes with energy recovery and 3-phase motors of class IE3. It has energy-efficient cooling of the control cabinet and linear scales without pressurization and is equipped with the DMG MORI auto-shutdown function as standard. These features are part of the GREENMODE, which reduces energy consumption by up to 10%.

Comfortable control options and autonomous operation

Integrated processes and energy-efficient machine utilization are just as much a part of the overall concept of the CTX 750|1250 as modern control options and automated production. The machine is optionally equipped with CELOS X on a SINUMERIK ONE or with an alternative MAPPS Fanuc. Both variants allow intuitive programming and fast machine set-up. DMG MORI Technology Cycles, such as gearSKIVING and gearHOBBING, facilitate the programming of demanding processes and expand the production technology possibilities of the CTX 750|1250. Production gains additional productivity through autonomous operation in three shifts. A wide range of automation solutions are available to users – from bar feeders and Robo2Go Max to the MATRIS system, which can be used to create complex production cells.